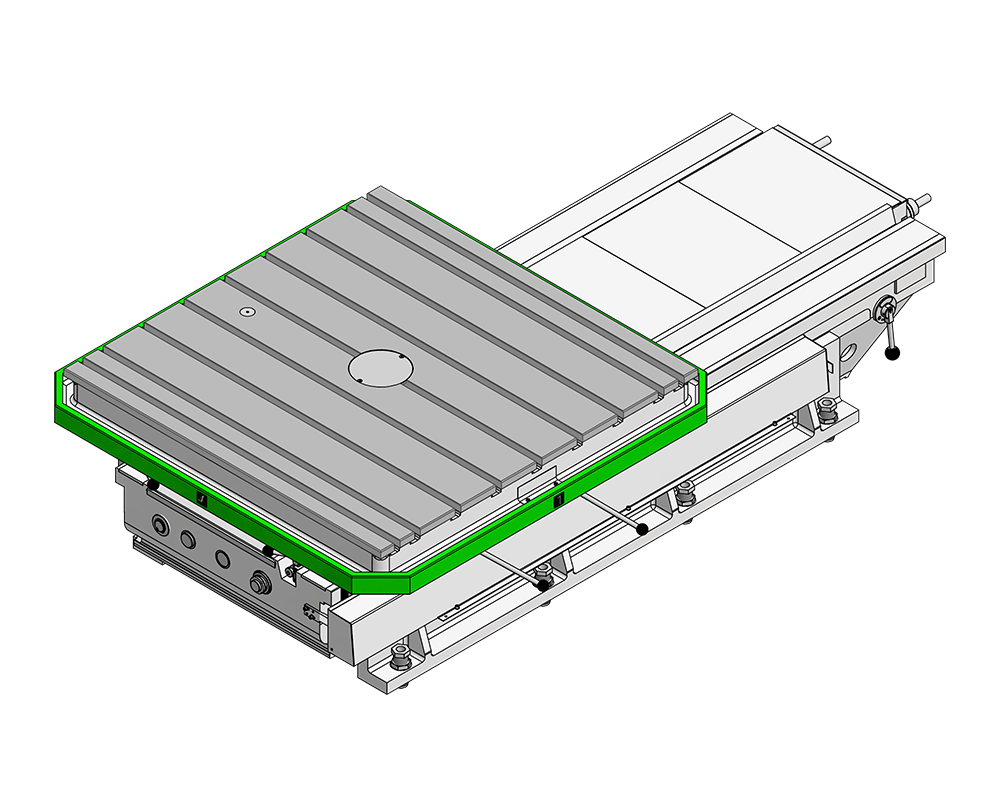

MT03X rotary table is an optional technological accessory for the RET10P and HP100 floor type horizontal boring and milling machines.

This rotary table is used as a secondary horizontal clamping surface for workpiece clamping and angular positioning in vertical axis (B axis) and shifting in one direction (V axis) including machine feed. Positioning in both axes is driven by motor or manually.

The clamping is performed on the main machine clamping surface (clamping plate) or on separate foundation.

MT03X rotary table is set on a clamping plate with a lifting device and fastened via T-slots and standardized clamps manually.

Anchoring to concrete foundation is performed using anchoring material similarly to the actual machine.

Main Parameters

| Table clamping surface | 1250 x 1250 | mm x mm |

| 1500 x 1500 | mm x mm | |

| Width of T-slots | 22 H8 | mm |

| Table loading capacity - 1250 x 1250 | 3000 | kg |

| Table loading capacity - 1500 x 1500 | 2500 | kg |

| Centering hole diameter | 180 H6 / 10 | mm |

| V… longitudinal travel of table | 1200 | mm |

| Voltage - manual version | 230 | V |

| Voltage - motor drive version | 3x400 | V |

| Table weight | kg | |

| Basic dimensions - length | 2705 | mm |

| Basic dimensions - width | 1400 / 1650 | mm |

| Basic dimensions - hight | 630 | mm |

SPECIFICATION

(technical specification v02.02)

Brief technical description

MT03X main components are high-quality grey iron castings with reinforcement ribs for high stiffness.

Travelling groups

- V axis – travel of saddle on bed

- B axis – table rotation

Kinematics and feed control

- motor and/or hand crank

- V axis – gear set + trapezoidal screw

- B axis – gear set + ring gear

- changing axes using lever on the bed

- switching on the motor drive with a button

Group guidance

- V axis – guideways on bed reinforced with hardened steel plates and ground, counterways with plastic casts

- B axis – guideways of the rotary table are scraped

Lubrication

- lubrication of the kinematics and the guideways is derived from the rotation of the driving shaft – pump

- central lubrication, connection to the lubrication system of the machine (optional)

Clamping

- manually by levers

Position measurement

- PZI version – preparation for additional installation of rotary encoder and DRO

- 4x90° optical readout

- HEIDENHAIN position measurement (optional) – incremental rotary encoder, incremental linear encoder + ND7013 DRO

CE - valid only for the European union

- the table is supposed to be integrated into the safety system of the technological site (machine) according to the applicable legislation and technical standards

ACCESSORIES

Standardly delivered accessories

- basic tool kit for operation and maintenance

- basic spares kit

- accompanying technical documentation including an operating manual

Optional accessories

- UK500, UK1000 clamping cube

- UU800, UU950, UU1120, UU1450, UU1620 clamping angle plates

- spares kit for 3-year operation