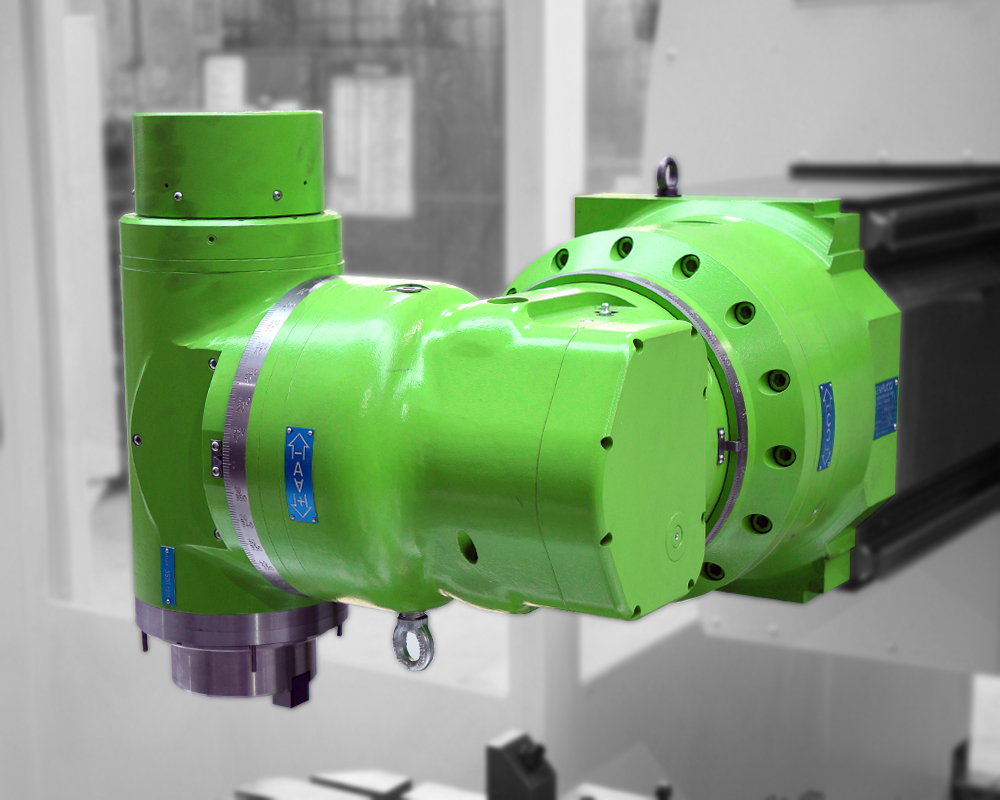

SEMPUCO KFU-D2/90 two-axis orthogonal automatic positioning milling head is designed for the RET10X, RET10P (RET100B in the machine version with ram) horizontal milling and boring machines as an optional technological accessory.

SEMPUCO KFU-D2/90 milling head can be used to mill and bore in any inclined plane.

Milling head is mounted on the head stock automatically.

Milling head is positioned automatically.

ОСНОВНЫЕ ПАРАМЕТРЫ

| Clamping taper | 50 | ISO |

| Tool shank | 69871 | DIN |

| Tool clamping force | 18 | kN |

| Max. tool diameter | 160 | mm |

| Max. tool length | 350 | mm |

| Max. tool weight | 30 | kg |

| Max. permissible spindle speed | 3 500 | rpm |

| Max. permissible transmitted power (from nominal speed) | 20 | kW |

| Max. permissible torque on the spindle (to nominal speed) | 600 | Nm |

| Nominal speed | 318 | rpm |

| Speed transmission from machine spindle to milling head spindle | 1:1 | |

| Angle range of the rotary part – C axis | +/-180 | deg |

| Angle range of the rotary part – A axis | +/-110 | deg |

| Hirth serration division for A/C axis positioning – standard/optional | 2,5/1 | deg |

| Precision of Hirth serration division | +/-3 | arcsec |

| Milling head positioning speed | 30 | rpm |

| Max. tangential load on Hirth serration | 5 000 | Nm |

| Max. feed force in the direction of the milling head spindle axis | 8 400 | N |

| Total milling head weight | ca. 400 | kg |