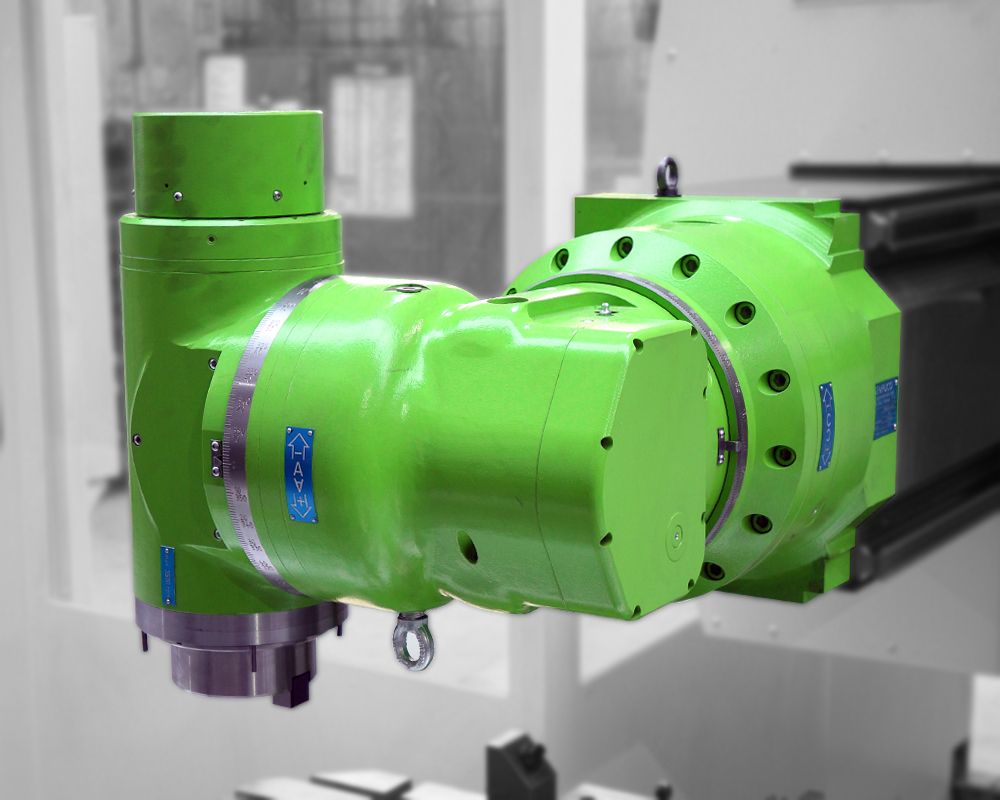

SEMPUCO KFU-D2/90 two-axis orthogonal automatic positioning milling head is designed for the RET10X, RET10P (RET100B in the machine version with ram) horizontal milling and boring machines as an optional technological accessory.

SEMPUCO KFU-D2/90 milling head can be used to mill and bore in any inclined plane.

Milling head is mounted on the head stock automatically.

Milling head is positioned automatically.

Main Parameters

| Clamping taper | 50 | ISO |

| Tool shank | 69871 | DIN |

| Tool clamping force | 18 | kN |

| Max. tool diameter | 160 | mm |

| Max. tool length | 350 | mm |

| Max. tool weight | 30 | kg |

| Max. permissible spindle speed | 3 500 | rpm |

| Max. permissible transmitted power (from nominal speed) | 20 | kW |

| Max. permissible torque on the spindle (to nominal speed) | 600 | Nm |

| Nominal speed | 318 | rpm |

| Speed transmission from machine spindle to milling head spindle | 1:1 | |

| Angle range of the rotary part – C axis | +/-180 | deg |

| Angle range of the rotary part – A axis | +/-110 | deg |

| Hirth serration division for A/C axis positioning – standard/optional | 2,5/1 | deg |

| Precision of Hirth serration division | +/-3 | arcsec |

| Milling head positioning speed | 30 | rpm |

| Max. tangential load on Hirth serration | 5 000 | Nm |

| Max. feed force in the direction of the milling head spindle axis | 8 400 | N |

| Total milling head weight | ca. 400 | kg |

Video

BRIEF TECHNICAL DESCRIPTION

The milling head consists of three compactly connected basic parts, which can be twisted against one another in order to achieve the required position of the milling head workspindle.

A precise and repeatable mounting of the milling head on the headstock is ensured by a joint with Hirth serration.

The angle of rotation in the milling head’s surface of intersection is set by entering the parameter into the control system. The milling head rotation is performed automatically. The milling head interior includes all the mechanisms for positioning in the A/X axes. The positioning is derived from the machine spindle rotation. A precise position determination and locking is ensured by the pneumatically/hydraulically controlled joint with Hirth serration.

SPINDLE

- the milling head workspindle is driven by the machine workspindle, thus its direction of rotation being identical to the machine spindle’s direction of rotation

- the milling head interior includes all the mechanisms for the milling head workspindle drive (gear wheels) and bearing (in precise spindle bearings)

- the tool is clamped in the milling head workspindle mechanically using disc springs. The tool is unclamped hydromechanically with pressure oil supply from the machine

- the tool is inserted into and removed from the milling head workspindle’s conical cavity manually or automatically (depending on the machine version)

- the way of controlling the clamping/unclamping of a manually inserted tool is identical to the controlling of the machine’s clamping mechanism

LUBRICATION

- the lubrication of the milling head workspindle bearing and the bearings of the individual parts of its drive is a permanent grease lubrication

TOOL COOLING

- by default, the milling head is adapted for tool cooling using cooling liquid supplied by external jets and/or through the workspindle axis. In the version with both cooling circuits, it is not possible to use both functions at once. The circuit with supply through the spindle axis provides the option of blowing the spindle cavity with compressed air

MOUNTING OF MILLING HEAD ON MACHINE

Automatic Milling Head Mounting

- an automatic milling head mounting is possible on the RET10X and RET10P machines

- in this case, the machines have to be equipped with a device for automatic head changing (AHC) with a PICK-UP system, which particularly consists of a rack for technological accessories customized according to the specific purpose of use and a cover plate for the headstock front, which protects the elements for clamping and connecting a milling head against contamination and damage, while the milling head is deposited in the rack

- the rack is permanently installed on the mobile auxiliary clamping pallet table (RET10X) or a clamping plate (RET10P)

- procedure of automatic milling head mounting on the machine

- Automatic pallet table travel (RET10X) or column travel (RET10P) to the AHC position

- Automatic headstock travel and removal of the cover plate from the headstock front

- Automatic headstock travel and mounting of the milling head (clamping of the milling head and connecting of the electrical/hydraulic/pneumatic lines)

Semiautomatic Milling Head Mounting

- a semiautomatic milling head mounting is possible on the RET10X, RET10P and RET100B (version with ram) machines. The rack for technological accessories is not permanently installed on the machine but deposited on the floor next to the machine. The rack can be moved by using lifting equipment

- procedure of semiautomatic milling head mounting on the machine:

- putting the rack with the milling head onto the worktable / clamping plate of the machine (touch probe required)

- automatic machine travel to the SHC position

- automatic headstock travel and removal of the cover plate from the headstock front

- automatic headstock travel and mounting of the milling head (clamping of the milling head and connecting of the electrical/hydraulic/pneumatic lines)

LIST OD STANDARD ACCESSORIES

- adapters for tool clamping - 5 pcs

- accompanying technical documentation including instructions for use