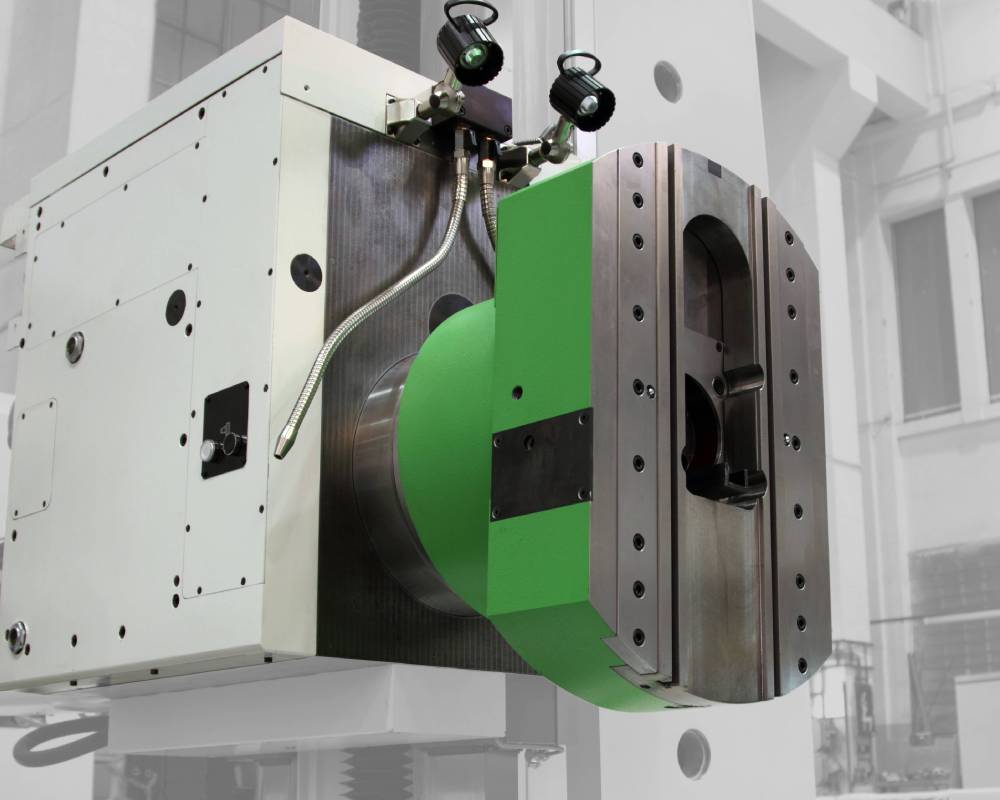

LD650 facing head is designed for RET100B, WH10-CNC, WHN13-CNC horizontal milling and boring machines as optional technological accessory.

Facing head can be used for face turning, inside and outside machining of cylindrical, conical and otherwise shaped surfaces of large diameters. The equipment is particularly suitable for the demanding technological operations by the use of full CNC control of the slide.

Facing head is mounted manually on the headstock (centring hole of the hollow spindle). Tool holder is positioned manually onto the slide.

Tool is mounted manually into the tool holder.

Main Parameters

| Facing head diameter | 650 | mm | |

| U... tool slide travel | 170 | mm | |

| Facing diameter range | 300 - 1000 | mm | |

| Inside boring diameter range | 300 - 1000 | mm | |

| Dimension / pitch of clamping T-slots | 12 H11 / 180 | mm | |

| Maximum facing head working speed | 150 | rpm | |

| Maximum spindle speed with mounted facing head | 200 | rpm | |

| Maximum torque | RET100B, WH10-CNC | 1640 | Nm |

| WHN13-CNC | 3322 | Nm | |

| Tool slide feed range | 1 - 1000 | mm/min | |

| Rapid traverse of tool slide | 1000 | mm/min | |

| Ratio of spindle stroke to tool slide travel | 1:01 | ||

| Cylindrical surface machining accuracy | IT 7 | ||

| Total facing head weight | 200 | kg | |

Gallery

Video

Specification

(technical specification v01.01)

Brief technical description

Facing head consists of an axisymmetrically rotating basic body with a hole in its axis through which the machine working spindle may pass and a tool slide travelling in the body perpendicularly to the axis.

Tool slide travel (U-axis) is backlash free driven by the spindle stroke. The position of the tool slide is automatically controlled by CNC control system.

All the slide-driving mechanisms are inside the body of the facing head except for the gear rack, which is clamped in the spindle taper.

The clamping T-slots on the tool slide provide for fixing of a tool holder, into which lathe or special tools are clamped.

At the basic position of the slide, with excluded input drive mechanism (rack) and dismounted tool holder, the machine spindle can be used for machining.

Machines equipped with an automatic tool changer (ATC) cannot use this function while the facing head is mounted.

Lubrication

Lubrication of the tool slide is provided with grease. It must be added as needed.

Lubrication of the drive mechanism is permanent with grease.

Mounting facing head on the machine

Facing head is mounted manually on the face of the hollow spindle using lifting equipment.

After placing the centring hole of the facing head onto the hollow spindle, the facing head is manually fastened using 4 screws.

Accessories

Standardly delivered accessories

- tool holder

- basic tool kit for operation and maintenance of the machine

- accompanying technical documentation including an operating manual