The story of Filip Salomon – a young shift foreman in heavy mechanics

Nearly seven years ago, Filip Salomon, who was a student at the then newly founded TOS VARNSDORF Secondary School of Industry, had his first day of practical training as an apprentice at our company RETOS VARNSDORF s.r.o. He was selected from among several students of the third graduation year in the field of mechanic adjuster and was supported by us for his academic achievements and approach to work during his studies until June 2020. After graduation, according to mutual agreement, he was hired and was immediately actively involved in the production process. He learned quickly and worked on his professional growth. A year ago, he was successfully promoted to the position of shift foreman in the heavy mechanical department.

We admire his personal story and believe he can be an inspiration to other young people. That's why we wanted to know what he had to say. With such single-mindedness, one would expect that he always wanted to work in engineering, but he surprised us a little in that respect.

What did you want to be as a child?

He laughs, "A farmer."

And why did you end up studying engineering?

"I didn't quite know what to study. I had a bit of a leaning towards it from my dad. He's a welder and a locksmith. I was young and indecisive, so I told my parents I didn't know and that I would give them a free hand. They recommended me to try the new TOS VARNSDORF school. So, I attended the school's training fair, and I liked it."

He already knew a little about machine tools and asked his parents what was being done at TOS. "It's one of the biggest factories here and I was interested, but when they told me about horizontal boring mills, I honestly didn't know what it was all about in junior high school."

How satisfied have you been with the practical training at RETOS?

"I was pretty happy from the start. First, I was on practical training at the light mechanics department and I liked it. The light mechanics foreman was kind of strict in terms of quality, but he was also fun. In a positive sense, he was strict just accurately.

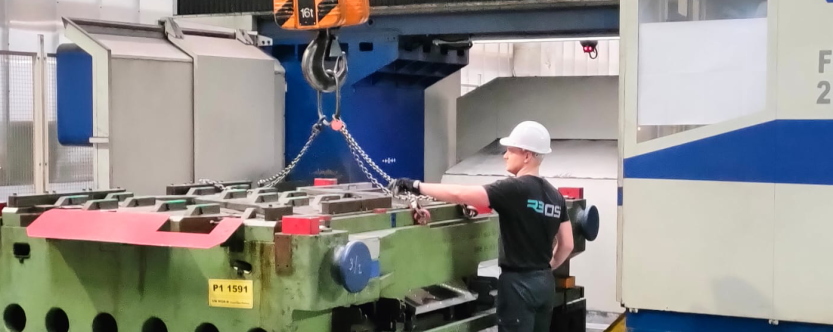

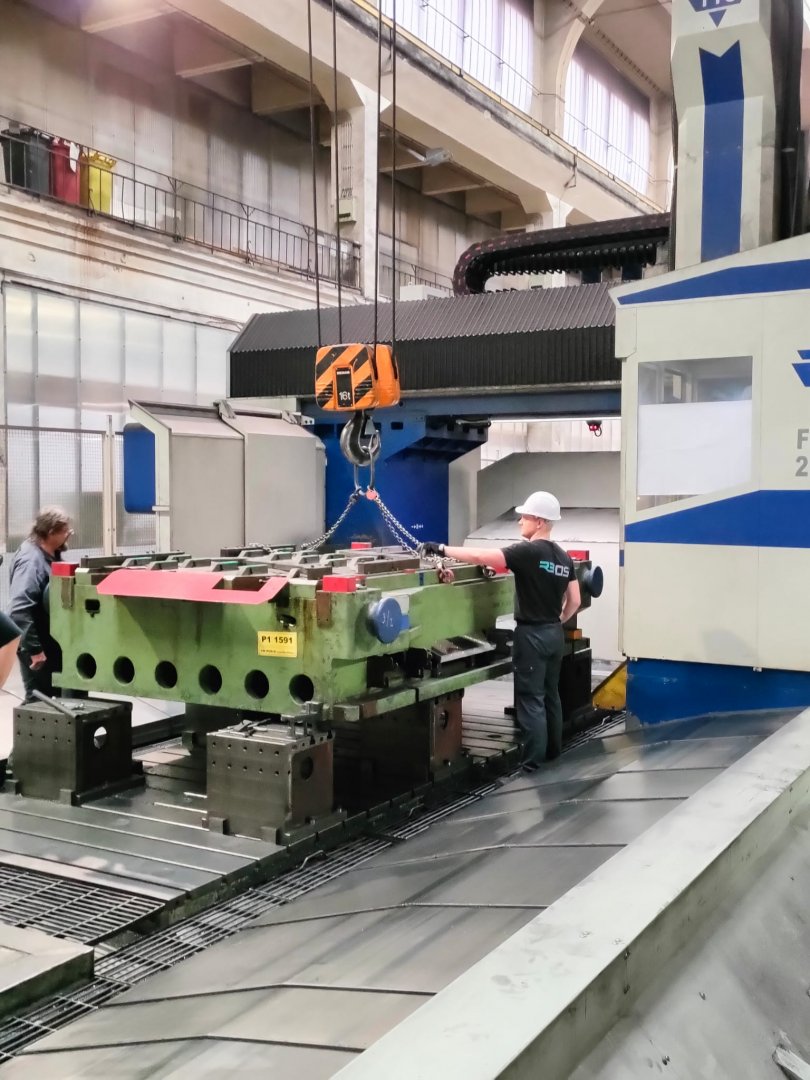

And then when I joined heavy mechanics, I was happy there, too. There were a few accidents," he recalls with an embarrassed smile, "but I was still happy. It was during my apprenticeship that I liked the fact that they do overhauls here, that it's not just stereotypical work with a drawing and a part, but that you have to know something about the workpiece."

Have you ever been afraid of large workpieces?

"I started right here, so I didn't really know the smaller ones. On the contrary, I'm amazed when I go somewhere and I see these small machine tools, when they're milling with that number one mill. For me that's rather cute. Then I even had problems with it on my final exam, because I was used to taking bigger swarf, even though it's not a gantry, but it still has several times the power of some of the smaller milling machines."

I'VE GOT USED TO THE BIGGER PARTS, SO I ENJOY THE BIGGER WORKPIECES MORE. I WOULDN'T WANT TO DO THE SMALLER ONES

Would you enjoy working on a smaller machine like a lathe?

"I've been on a lathe once or twice for practice, but the lathe doesn't really appeal to me. I've got used to the bigger parts, so i enjoy the bigger workpieces more. I wouldn't want to do the smaller ones," he says happily.

The excitement of large workpieces is not a matter of course. That's why we are particularly pleased that Filip has found his fulfilment in it. With his active approach and advice, he can motivate even colleagues who have no experience with large workpieces.

As a shift foreman, he tries to maintain substitutability in the workplace and sometimes works on other machines himself.

"Of course, I also enjoy trying my hand at another machine when someone drops out on a shift. And that has already happened, for example on the WHN13."

"There have been a few times when I've had to go to the conventional boring mills when a machine was being repaired and our machine shop manager needed me elsewhere, so I've learned on those conventionals as well. It's interesting. The old machines are a diversion."

What do you appreciate most about your job?

NOT ALWAYS THE SAME

"Thanks to the small batch or piece production, it's not always the same. About 50 percent of the production is the same, so you have some certainty, and then, in the second part, you don't know what's coming because it changes. The overhauls that are routinely done at RETOS are each different. And then there might be a completely special one, like we have now – that extended bed that doesn't even fit the machine length-wise.

IT'S A CREATIVE JOB, WHICH MEANS YOU LEARN THAT MUCH MORE

It's a creative job, which means you learn that much more. If I'd been doing six parts over and over all my life, I'd soon get tired of it. We have to be able to handle the technology ourselves when we're working, unless it's some specialty or collaboration that the technologist is handling."

Would you enjoy being a technologist one day?

"Absolutely, I'd enjoy it. It's interesting. It's a step forward again."

Filip is always working on himself and is not discouraged by new challenges. Maybe it's also the nature of an athlete. Until his senior year Filip competitively swam. In our opinion, this is a great approach and we want to support him with that. After all, the position of a shift foreman does not have to be the peak of career.

What was the biggest challenge in your career?

“The biggest challenge was, when I newly had to work on my own without Thomas, with whom I had been together on the shift all the time before that and who trained me. Then there was Covid-19 and he had to stay at home in quarantine. Thus, I remained there without his support.”

How did you manage this situation?

“I had to check everything three times. Just then I received an unusual workpiece, a weldment which is not quite easy to machine. So, I tried to make use of all my knowledge and experience, Thomas had given me. I had to call him about twice, and in the end, I somehow managed it.”

Now, as a shift foreman, you must be able to take care of yourself, but also manage people. How are you doing?

"I would say, positively. I got along well with everyone all my life. Managing people is a completely different skill than working on a machine, but I try to accommodate everyone when I can. After all, my colleagues also have a lot of experience."

Filip already had several apprentices. He knows exactly how they feel and what helps them because he was once in the same position himself.

"When I have an apprentice here, I try to tell him some extra useful things, for example, when we have a program going and all he should do, was watching it, I take him aside and try him on naming tools, which might come in handy one day even for graduation."

What advice would you give to a student interested in engineering?

"If someone likes Lego-type kits, they can act out a bit here, because even the clamps and so on are de facto like a big kit," laughs Filip. "I also enjoyed building with blocks myself when I was little, and here you have a little reminder of your childhood. Machining is actually putting something together."

"I LIKE THAT THE RESULT OF THE WORK CAN BE SEEN."

So, even though he originally wanted to be a farmer, he ended up fulfilling at least one childhood dream. Come play a little, too.

Thank you, Filip, for a pleasant interview.

Radka Soudková (HR) a Julia Švarc (marketing)