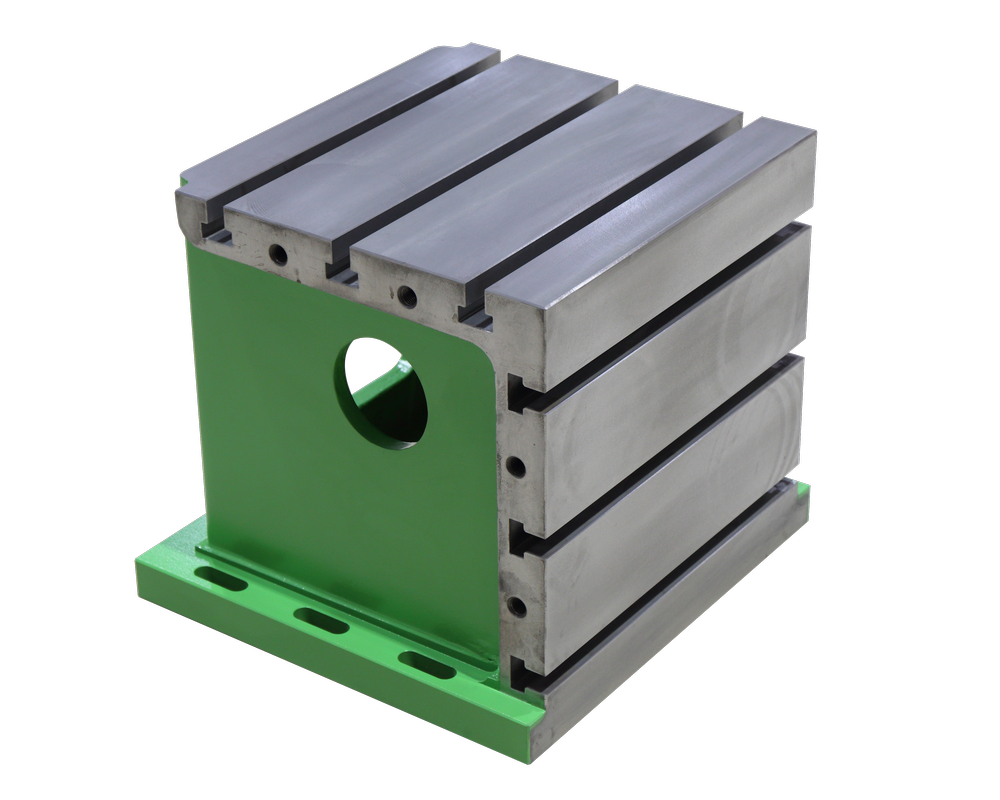

UK clamping cubes are optional accessories for horizontal boring and milling machines.

A clamping cube is a device used for workpiece clamping.

The clamping is performed on the machine's main clamping surface (table or clamping plate).

UK clamping cubes are fastened via T-slots and standardized clamping claws manually using lifting devices.

Main Parameters

| Designation | UK500 | UK500 | UK1000 | UK1500 | UK2000 | UK2500 | UK3000 |

| Version (standard) | PN 243230 | NPP 225 | |||||

| Hardness of functional surfaces | 190 ± 10 HB | ||||||

| Loading capacity [kg/0,25m2] | 12000 | 15000 | |||||

| Clamping slot width | 22 H12 | ||||||

| Clamping slot pitch | 160 | ||||||

| Clamping slot amount | 3+3 | 2+1+1 | |||||

| Thread holes | M20 | ||||||

| Height | 500 | ||||||

| Width of clamping/foot surface | 500 / 560 | 500 | 1000 | 1500 | 2000 | 2500 | 3000 |

| Depth of clamping/foot surface | 480 / 530 | 400 | |||||

| Weight [kg] | 300 | 400 | 800 | 1200 | 1600 | 2000 | 2400 |

SPECIFICATION

(technical specification v01.00)

Depending on the size, are offered two clamping cube versions – see illustrations/standards.

Brief technical description

UK500 – UK3000 clamping cubes are high-quality gray iron castings with reinforcement ribs for high stiffness.

The cubes‘ clamping surfaces have T-slots and thread holes.

Geometric accuracy

During clamping, it is necessary to align the UK in order to obtain the required geometric accuracy.

Geometric accuracy can be improved by finishing the clamping cube directly on the machine on which it will be used.