In cooperation with Rajmont, RETOS launches new hardening machine

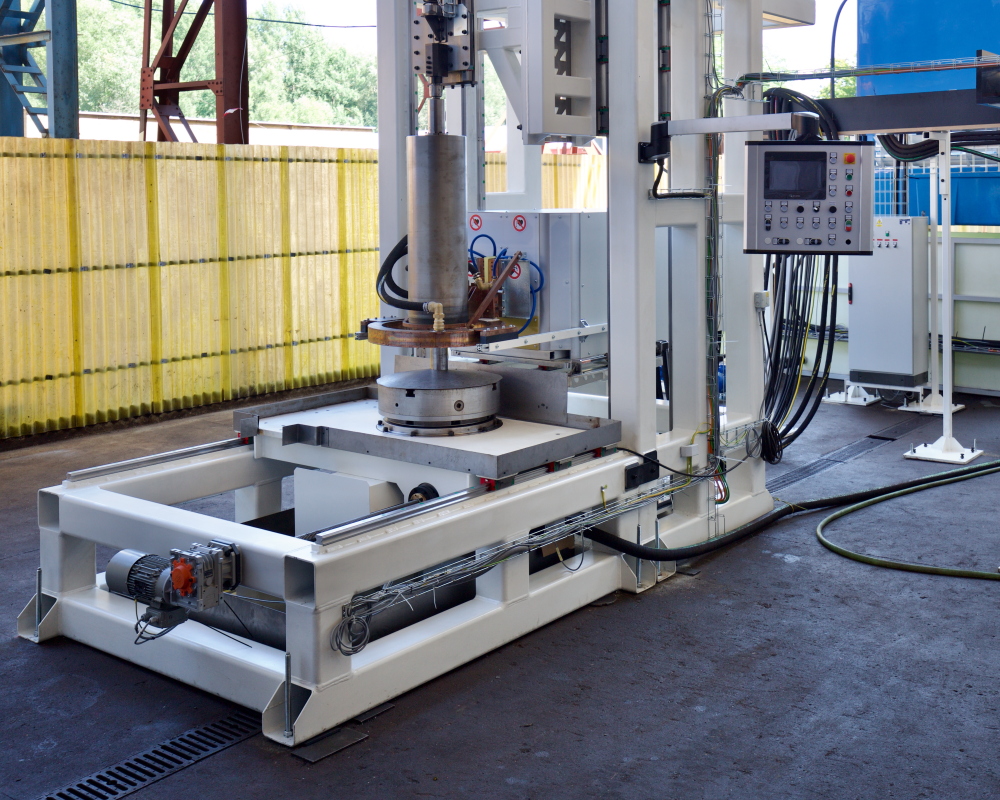

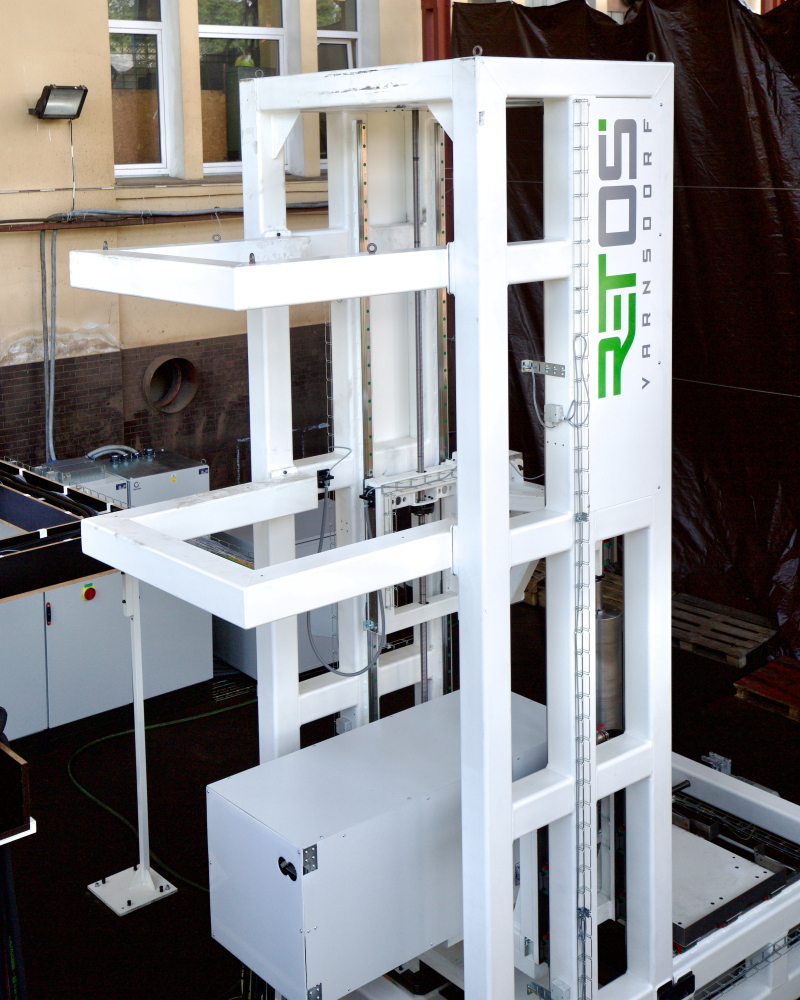

RETOS VARNSDORF s.r.o. has expanded its portfolio with a new hardening machine. The development was carried out in close cooperation with Rajmont s.r.o., a leading manufacturer of hardening machines in Europe. The machine is one of the largest of its kind in Central Europe and is a true one-of-a-kind.

The project began about two years ago, when a customer approached RETOS with the request to build a hardening machine based on the WHN13CNC horizontal boring mill. “The machine needed to harden the customer’s parts – up to 6 meters long, up to 350 mm in diameter, and 3 meters hardening length,” explained Petr Litava, Technical Director at RETOS. For RETOS, this was a challenge, as the company had no prior experience with induction hardening. “It was a big gamble, but we wanted to try something different,” said Litava.

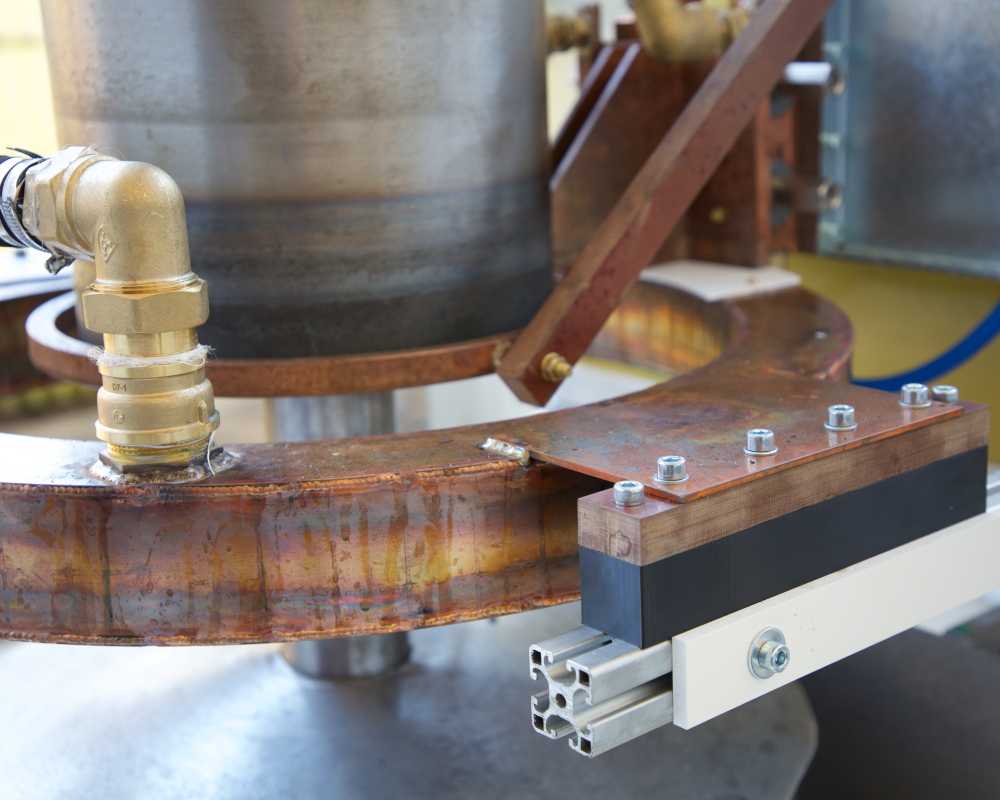

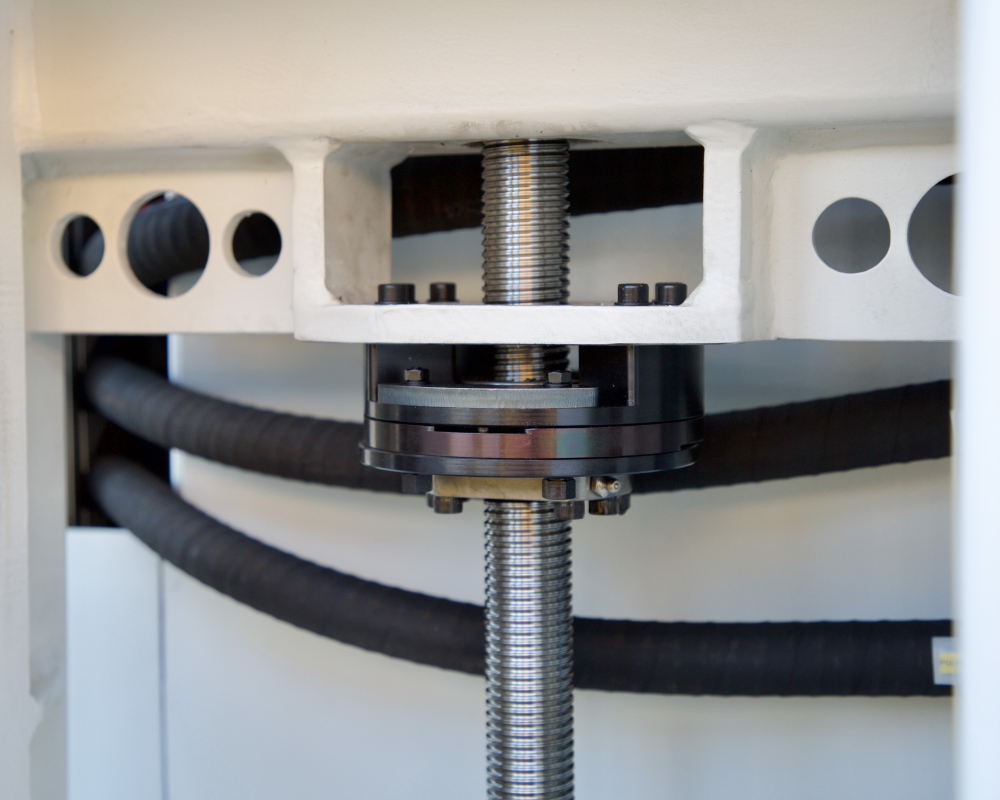

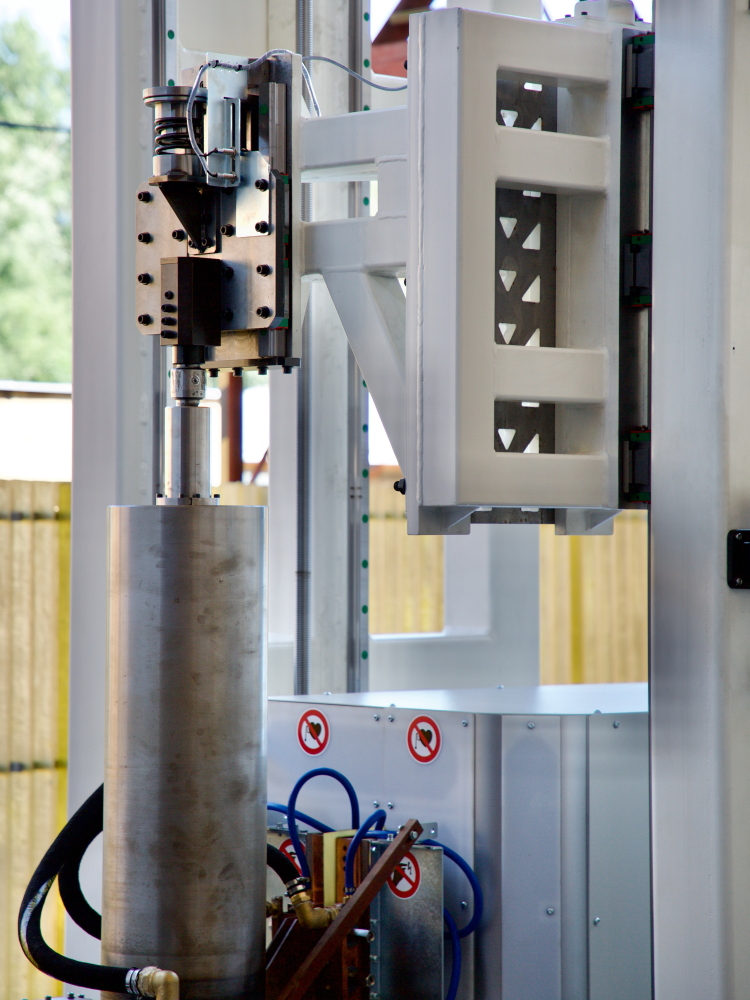

About a year ago, RETOS and Rajmont agreed on a cooperation. At the same time, it became clear that the machine could not be built on the WHN13CNC base: the axes were suitable, but the design and shape were not. RETOS therefore developed a customized, single-purpose machine, supported by extensive documentation from Rajmont, which already had similar machines in its portfolio. “The customer had parts that nobody in Europe could harden. We designed, built, and commissioned a machine to do it,” said Zdeněk Rajmont, owner of Rajmont. Together, RETOS and Rajmont adapted the machine to the customer’s requirements and “fixed the original machine’s shortcomings.”

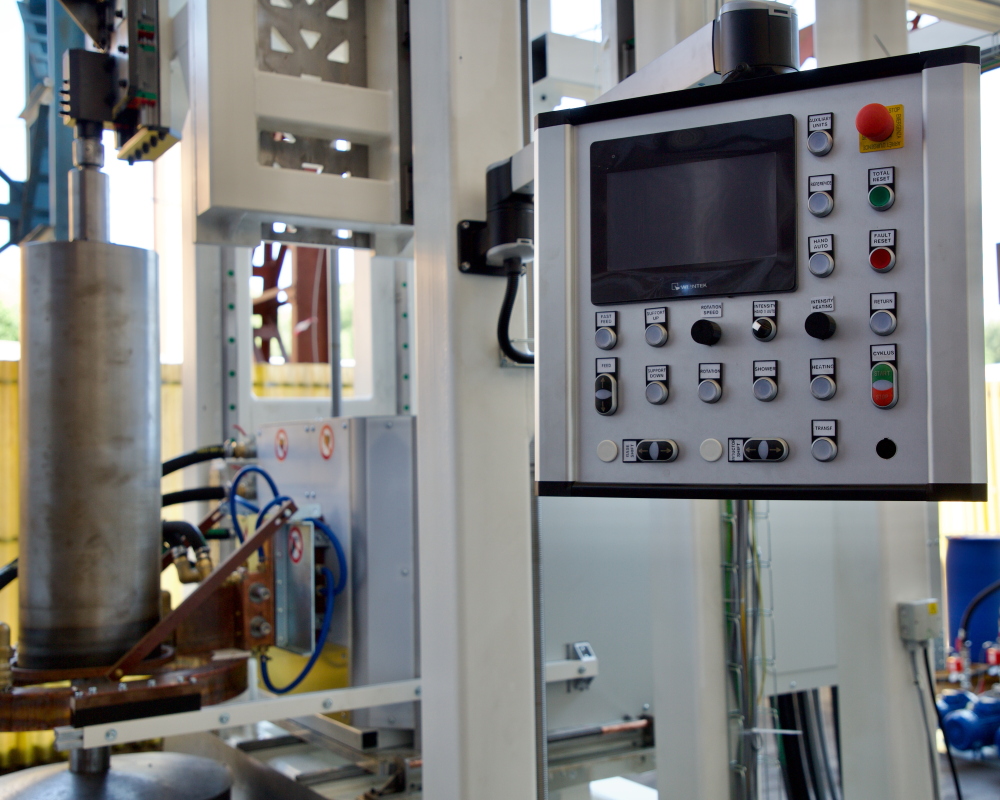

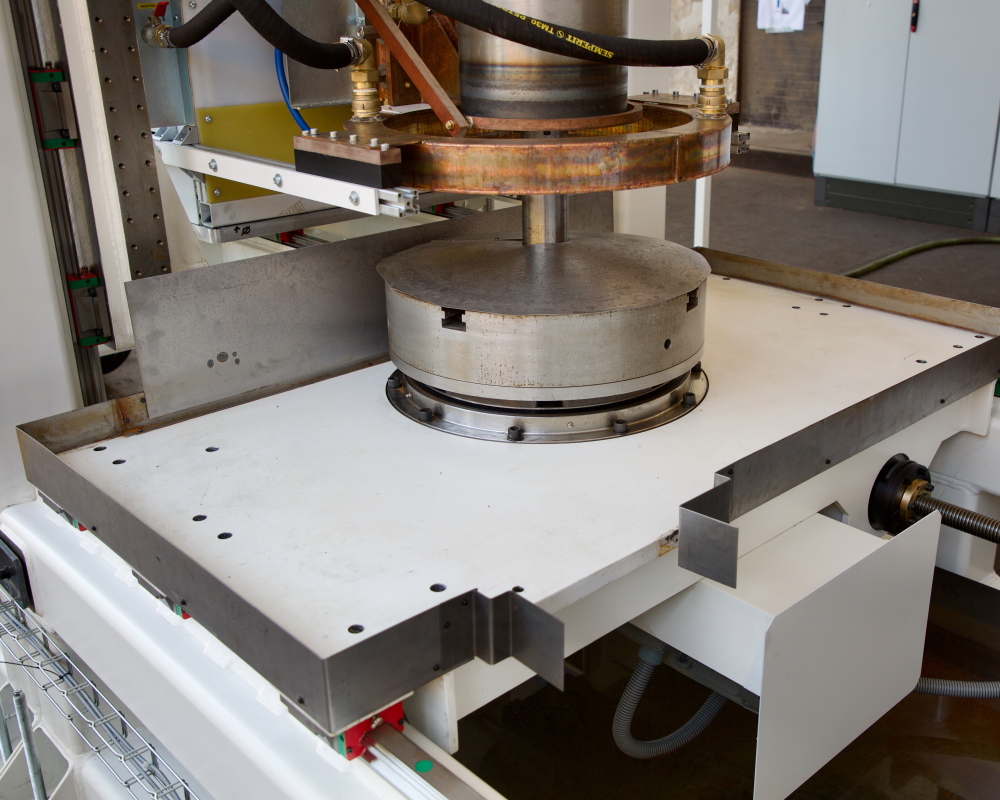

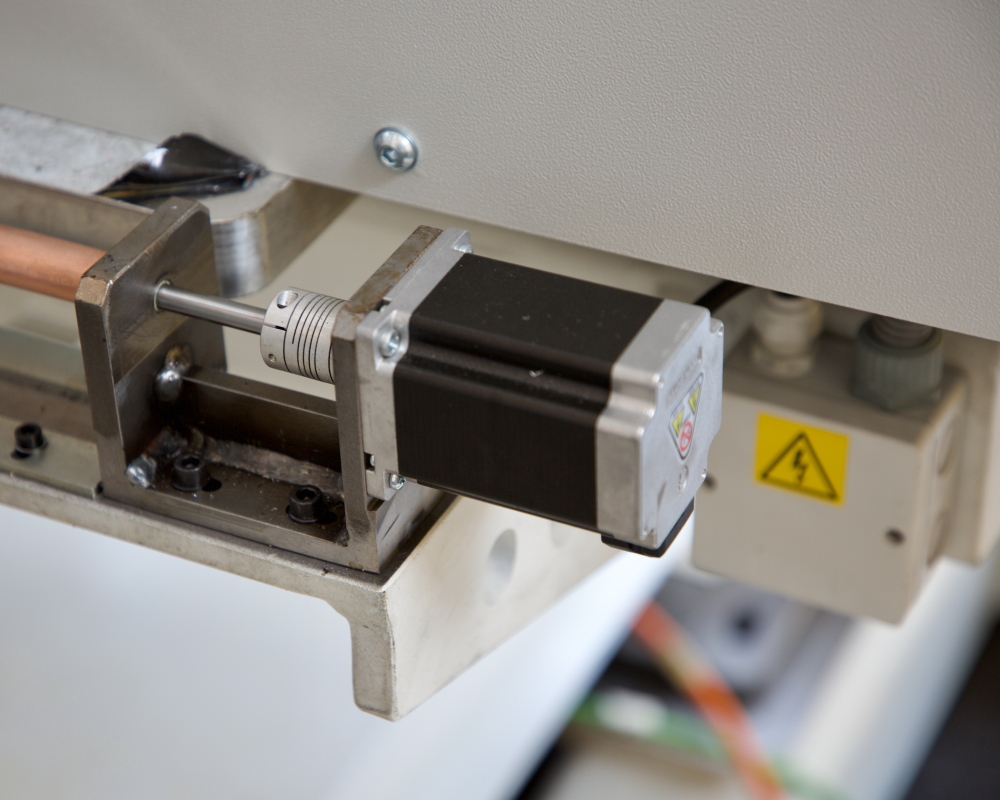

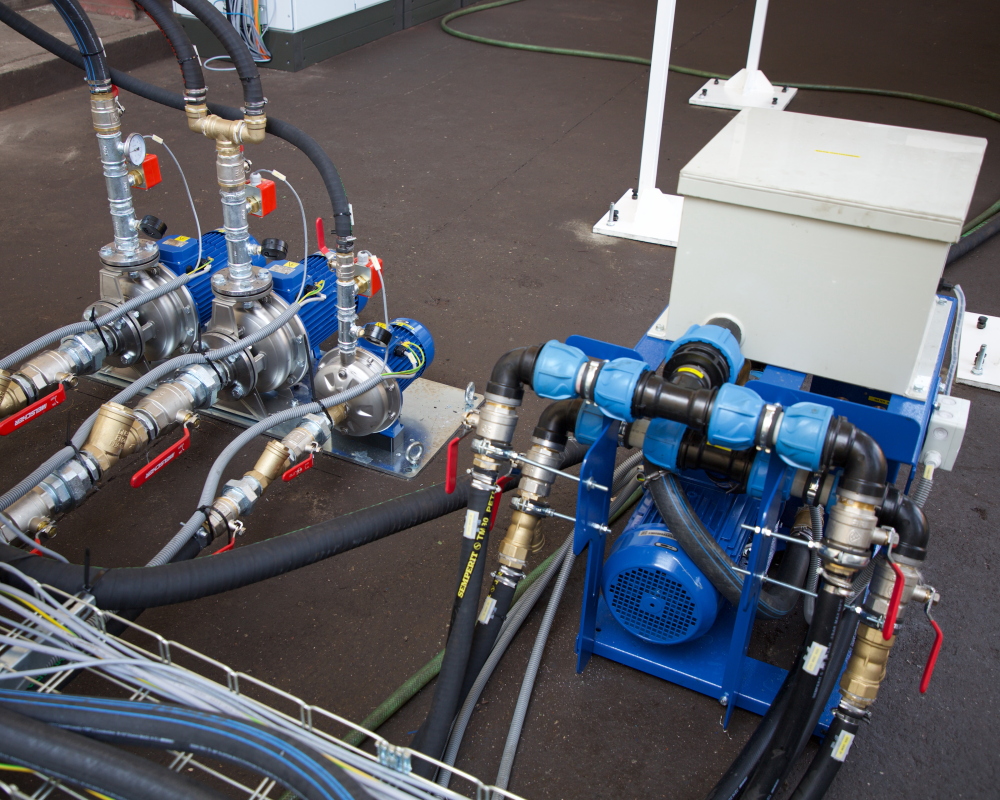

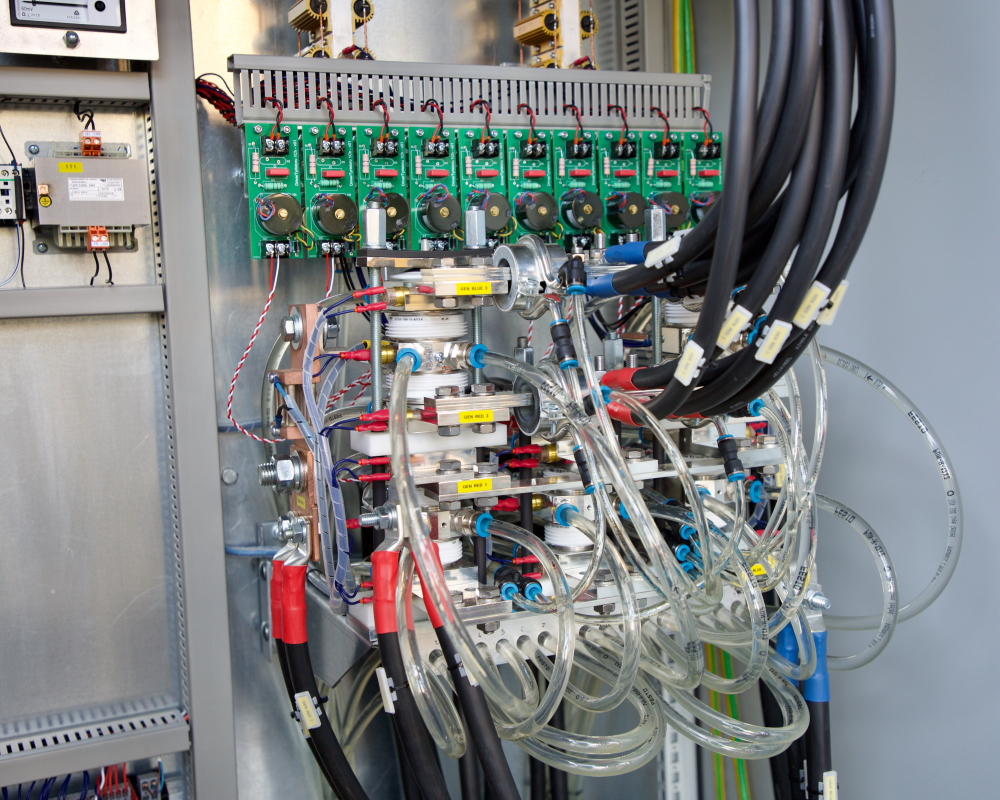

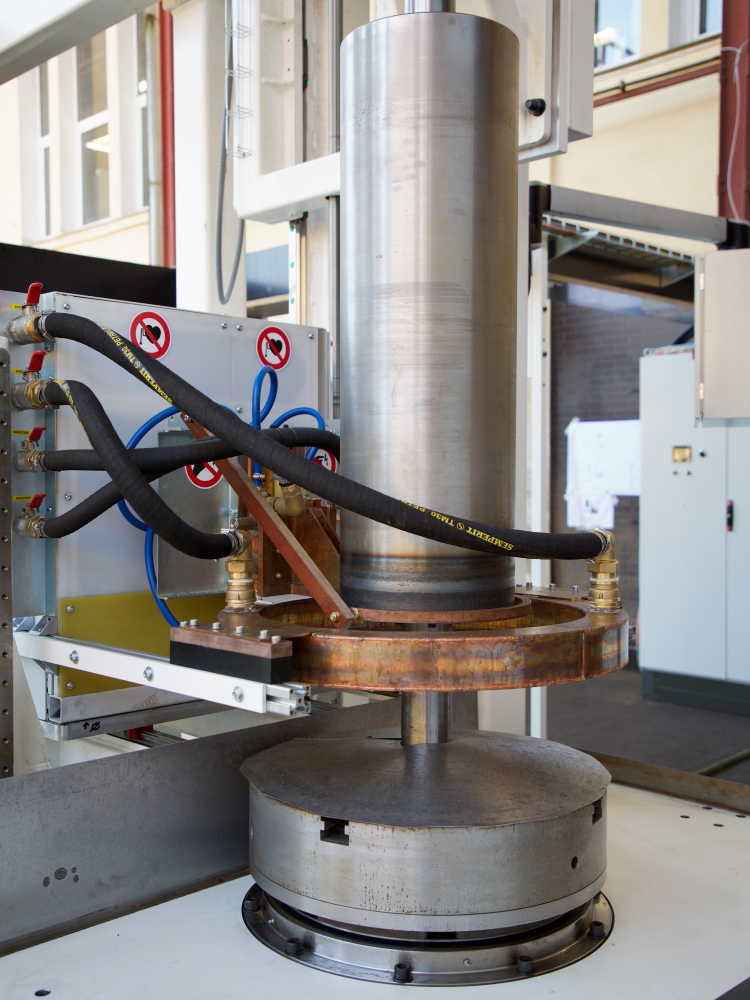

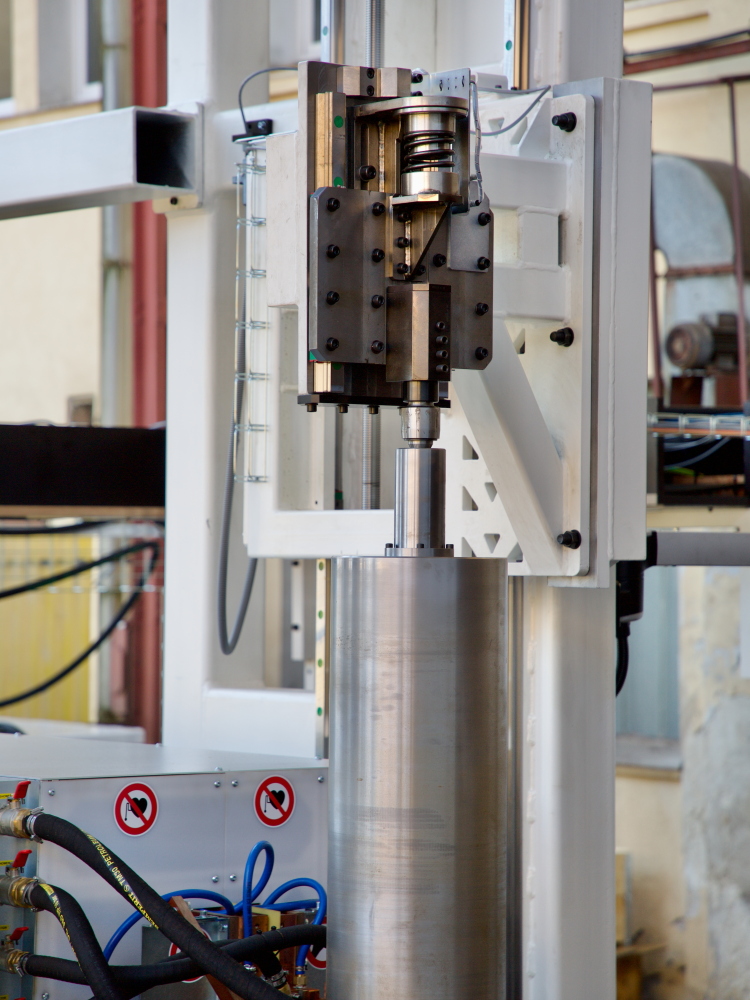

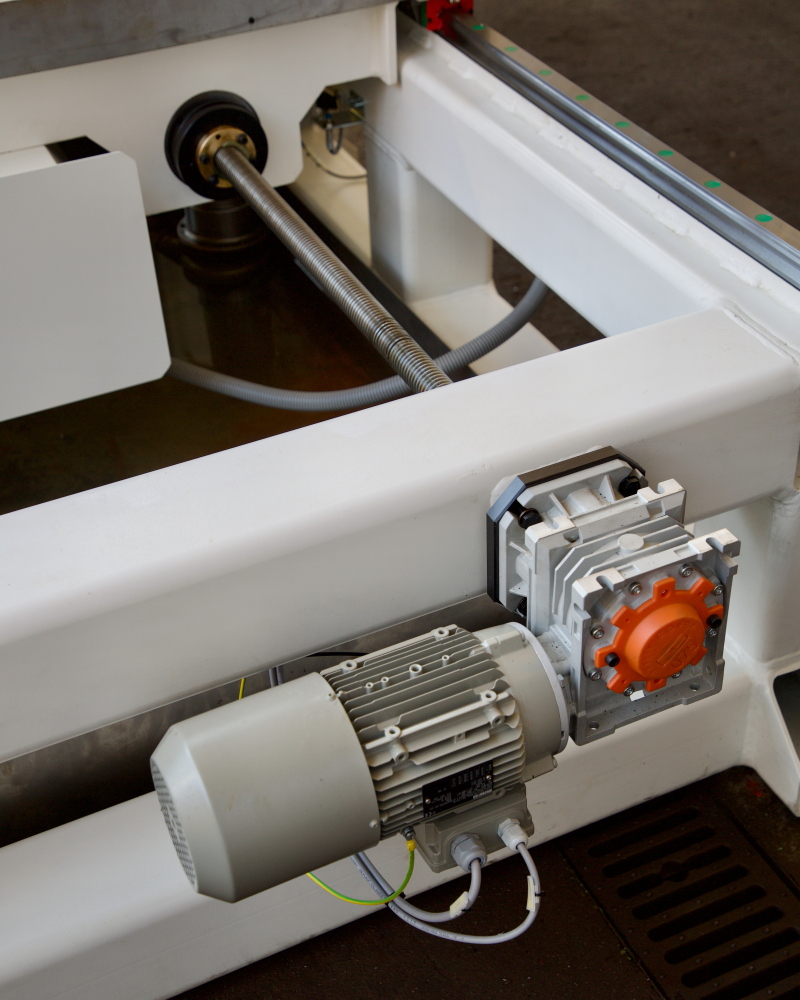

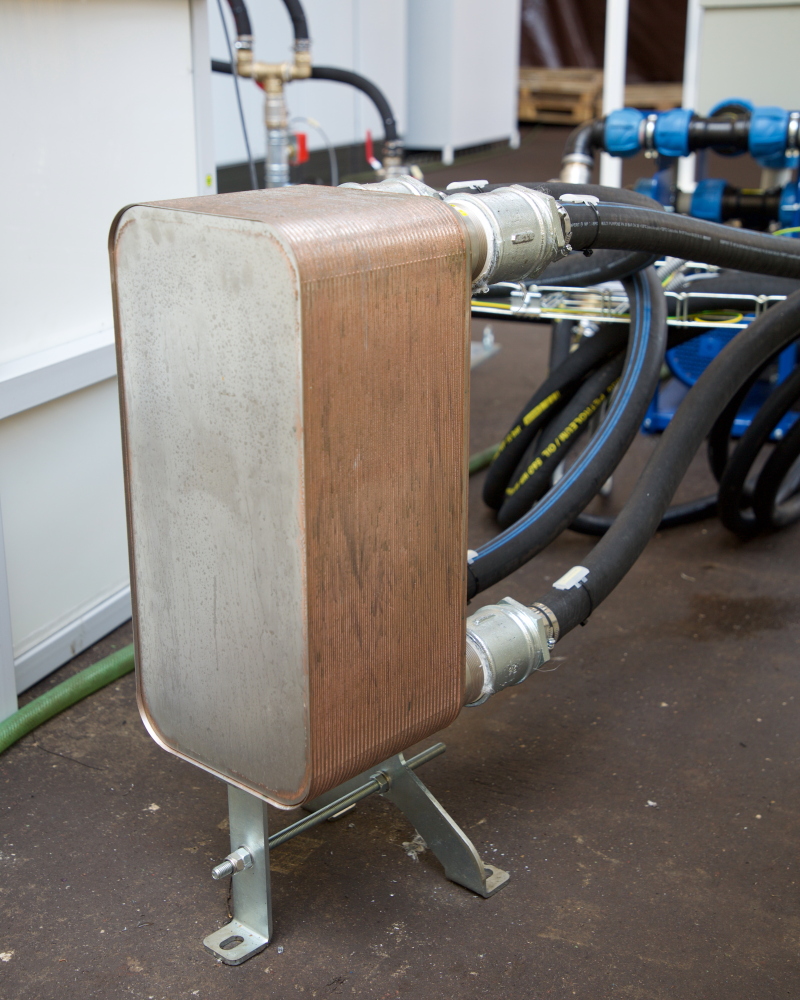

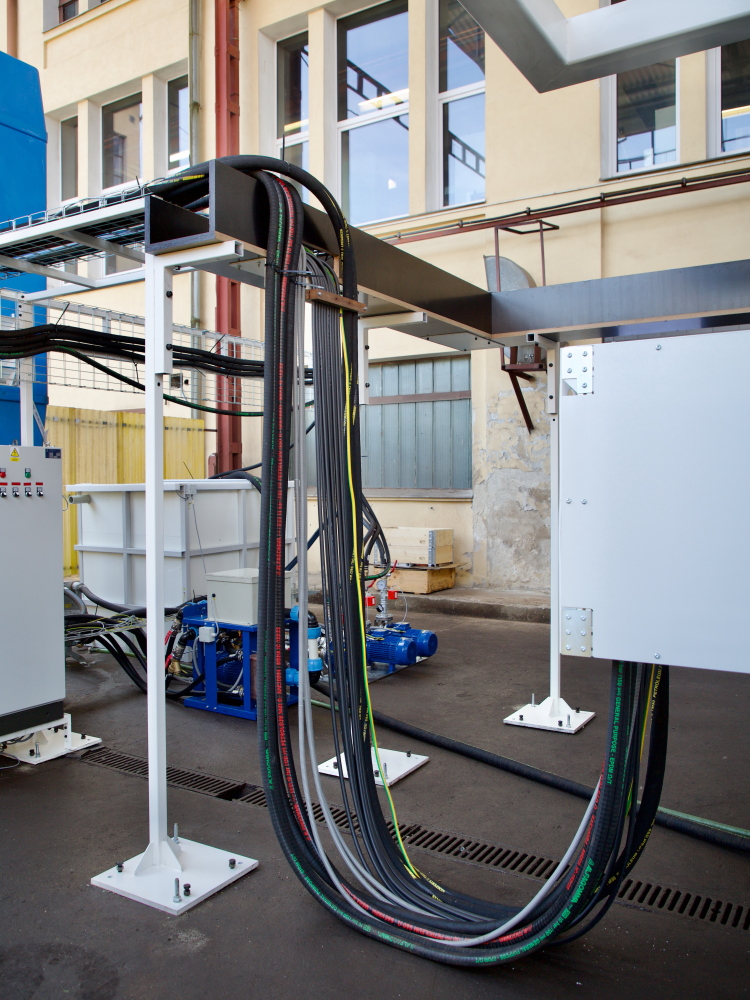

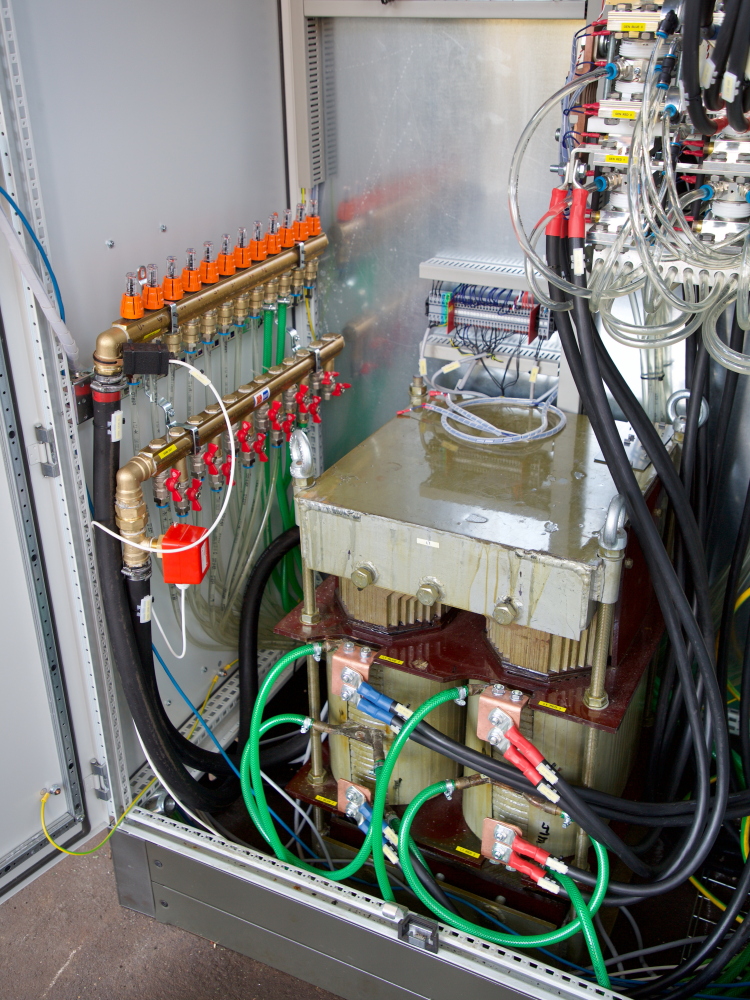

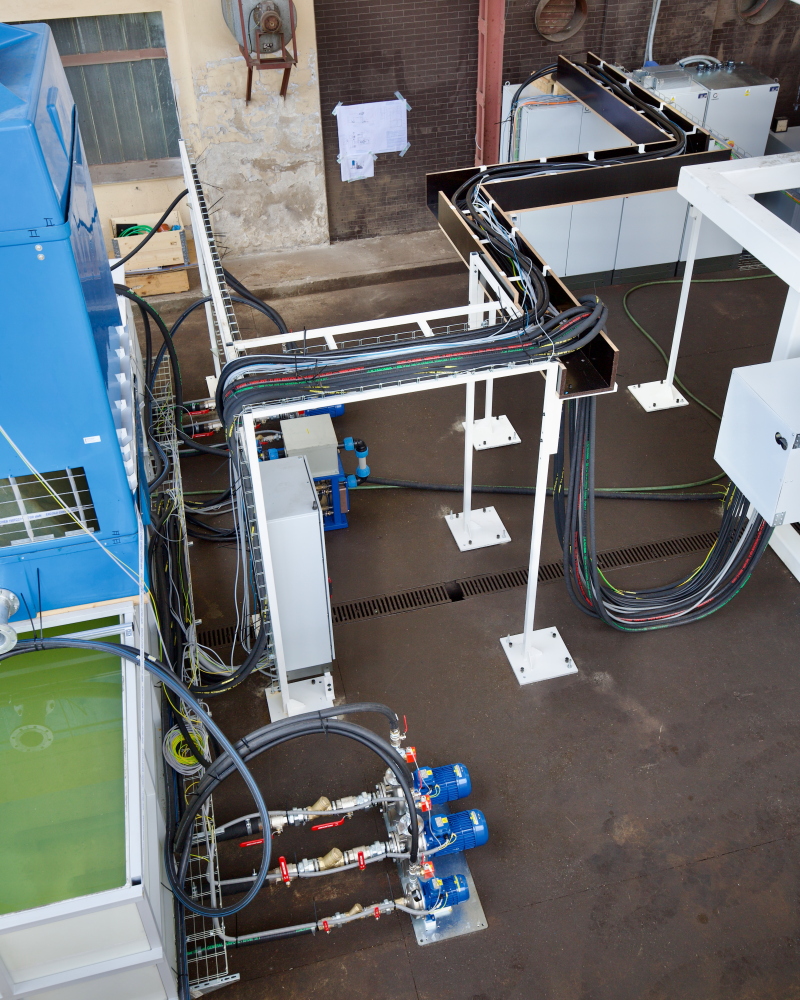

Rajmont was responsible for all electrical cabinets, wiring, transformers, water circuits, and the entire cooling system. RETOS produced the mechanical components such as the frame for the hardening transformer, tailstock and lunette for clamping and guiding the workpieces, and support structures for hoses and cables.

Preparation took three months, production and pre-assembly six months. Due to the high power of 630 kW, testing was conducted in two phases: first at Rajmont, which had the necessary power supply, then at RETOS, where the machine was assembled for four weeks and tested for one week – even though at only one-third of full power.

PARAMETERS

| Max. hardening transformer power | 630 kW |

| Input current at full load | 1100 A |

| Max. hardening length | 3000 mm (workpieces clampable up to 6000 mm) |

| Max. workpiece diameter | 380 mm |

| Max. workpiece weight | 1250 kg |

The whole machine, including technology, has a footprint of 11 × 7 m and a cooling tower outside the hall. The machine’s height is 5.5 m.

For future customers, the machine doesn’t have to look the same. “We’re flexible and can adapt the parameters to different customer requirements. There won’t be only this version. Of course, we could produce an exact copy, but if a customer has other requirements for its dimensions, he will get a customized machine. It can be adapted both in dimensions and hardening orientation (vertical or horizontal). Moreover, during testing, we came up with several ideas for further improvements.

RETOS is specialized in manufacturing, overhauls, and modernization of horizontal boring mills, while Rajmont produces induction heating devices and generators for induction hardening and soldering as well as for further heat treatments. The companies worked together for the first time and plan to continue the collaboration. “It worked perfectly. RETOS’ approach was excellent,” said Rajmont. Litava agrees. For RETOS, the machine is a new portfolio product, for Rajmont, it is a showcase machine.

If you want to learn more about the RKS630V, click here.