- no matter what the original type is (from WHN9A to WH10CNC) the machine after upgrade reaches parameters comparable to a new one

- new or upgraded headstock up to 2500 rpm

Main Parameters

| Workspindle diameter | 100 | mm |

| Clamping taper | 50 | ISO |

| Spindle speed range | 10 - 2500 | rpm |

| Transversal table travel (X) | 1200 | mm |

| Vertical headstock travel (Y) | 900 / 1150 | mm |

| Longitudinal table travel (Z) | 950 | mm |

| Spindle stroke (W) | 710 | mm |

| Table clamping surface | 1000 x 1120 | mm x mm |

| Table loading capacity | 3000 | kg |

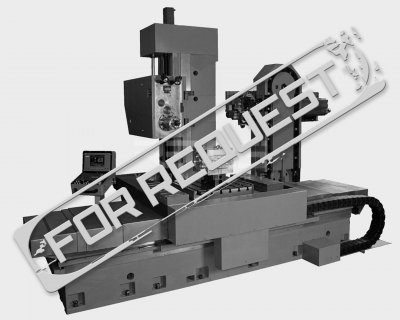

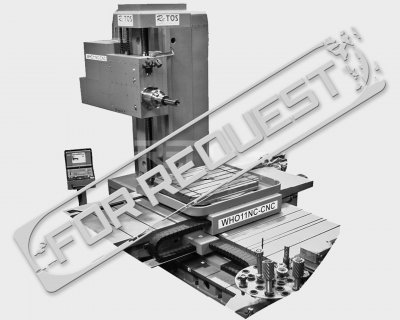

Gallery

Complete Parameters

| Machine parameters | ||

| Workspindle diameter | 100 | mm |

| Clamping taper | 50 | ISO |

| Tool shank | 69871 | DIN |

| Clamping adapter – screw | 4100793 | TOS |

| Spindle speed range | 10 - 2500 | rpm |

| Main motor power (S1/S6-40%) | 22 / 34 | kW |

| Maximum torque of the spindle (S1/S6-40%) | 2173 / 3250 | Nm |

| X...transversal travel of table | 1200 (1250*) | mm |

| Z...longitudinal travel of table | 950 (940*) | mm |

| Y...vertical travel of headstock | 1150 (1100*, 900**) | mm |

| W...spindle stroke | 710 | mm |

| Table clamping surface | 1000 x 1120 | mm x mm |

| Width of T-slots | 23 / 24 H8 | mm |

| Table loading capacity | 3000 | kg |

| Feeds... X, Y, Z, W – manual mode | 4 – 500 | mm / min |

| Feeds... X, Y, Z – automatic mode | 4 - 8000 | mm / min |

| Feeds... W – automatic mode | 4 - 6800 | mm / min |

| Rapid traverse...X, Y, Z | 8000 | mm / min |

| Rapid traverse...W | 6800 | mm / min |

| Rapid traverse of table rotation...B | 3 | rpm |

| Total power consumption | 50 | kVA |

| Machine weight | 13000 | kg |

| Machine and accessories standard colour | white 9010 / green 6018 | RAL |

| Fence standard colour | black 9011 / yellow 1018 | RAL |

| Total area including CE – approximate | 5500 x 6500 | mm x mm |

| * valid for machine frame WH10CNC | ||

| ** valid for machine frame WHN9A/B/C | ||

Technical specification

(technical specification 05.03)

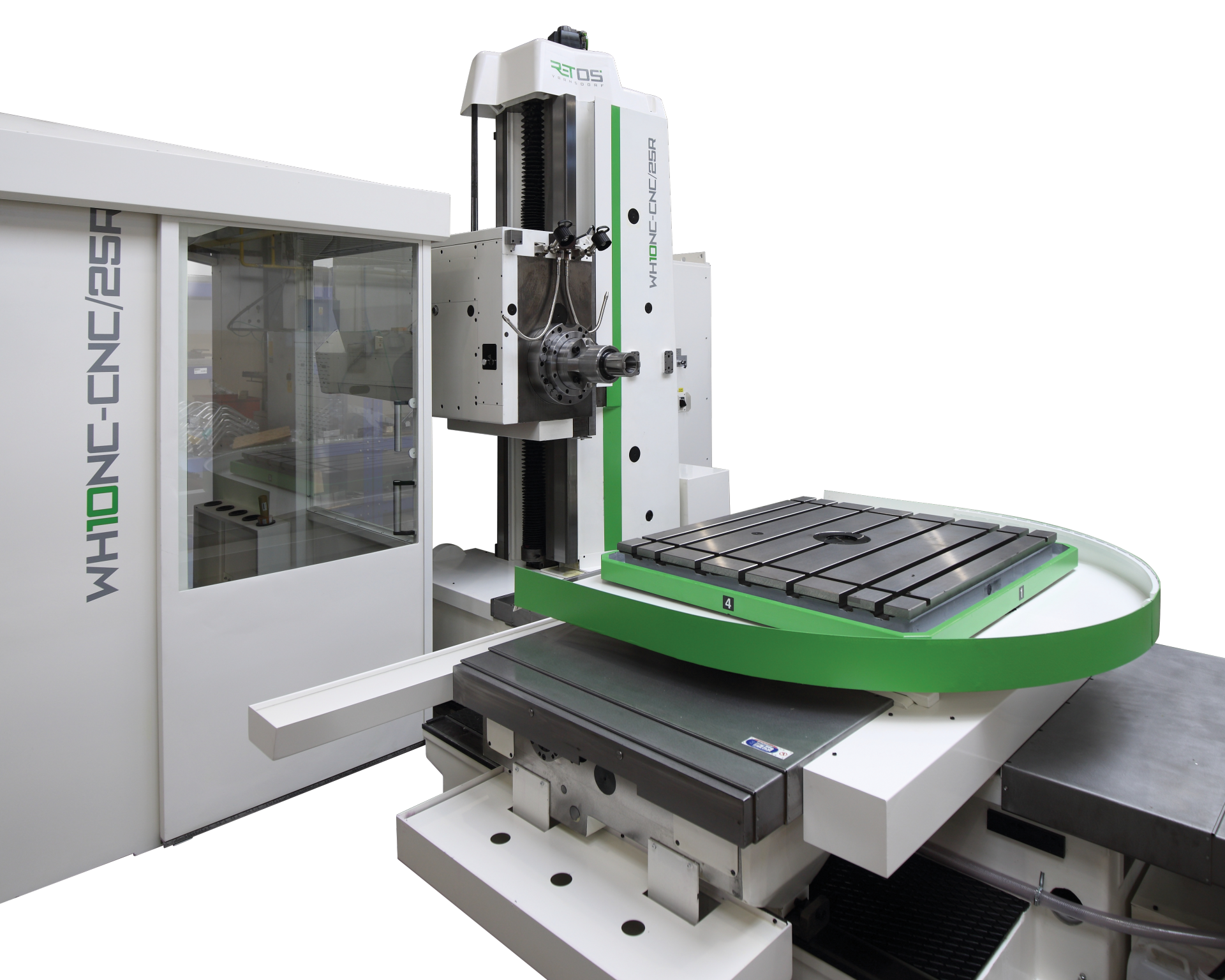

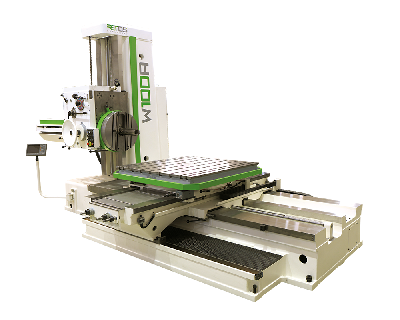

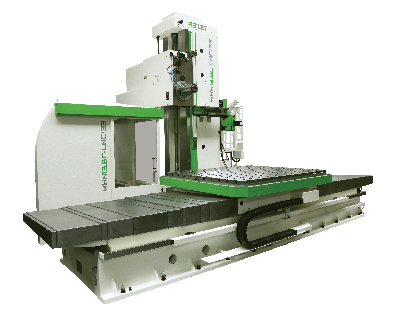

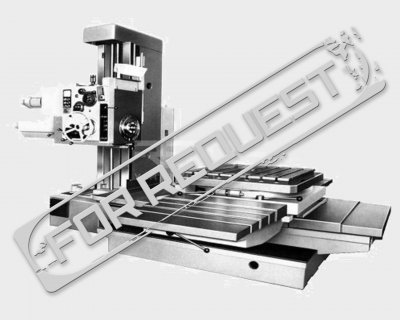

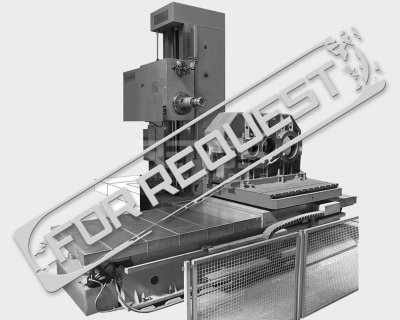

WH10-CNC/25 – Horizontal Boring Mill – Table Type

This document covers all the machines developed from this type. After the overhaul, they all have the same design and differ only in details.

Features

- contouring horizontal boring machine

- fixed column, crosswise travelling table

- 4 linear axes, rotary table

- sliding workspindle

- machine designed for universal application in engineering production

- suitable for roughing as well as for finishing

- optionally can be fitted with tool magazine with manipulator (ATC), tool cooling kit (CHZ), cooling through spindle axis (CHOV) or oil-mist cooling

- ready for "Industry 4.0"

Controlling of the Machine

- all functions of the machine, except tool clamping and unclamping, are controlled via the control panel, which consists of a keyboard, a switch panel and an LCD monitor

- the tool clamping and unclamping is controlled by switches on the headstock

- the control panel is completed with a portable control panel (handwheel), which duplicates some basic functions of the control of the machine

- the control panel is swivellingly connected to the wall inside the operator housing

- the control system allows manual, semiautomatic and fully automatic modes

- the standard communication interface allows connection with ethernet for easy administration and distribution of technological programs machine operation monitoring, diagnostic or service works of the control system, etc.

- machine design can be customized

Standard Version

Control System

- HEIDENHAIN TNC 640 + handwheel

- HEIDENHAIN drives

- SIEMENS motors

Powered Axes

- X – travel of rotary table slide on saddle

- Z – travel of saddle on bed

- Y – vertical headstock travel on column

- W – spindle stroke

- B – table rotation

- S – workspindle rotation

Machine Capabilities

- X, Y, Z, W axes powered in interpolation

- B axis powered only positionally

- linear interpolation of four axes

- circular interpolation of two of four axes powered in interpolation

- spiral interpolation

- spacial interpolation – spline in space

- interpolation of S and Z (W) axes – spindle turning depending on the Z (W) axis position – enables thread cutting without use of a compensating bushing

- technological possibillities may be limited by the territorial implementation of the NC program of the control system

Kinematics of the X, Y, Z, W Axes

- brushless digital servomotor with servo-drive

- clearance-free gearing by timing belt

- ball screw

Kinematics of the B Axis

- brushless digital servomotor with servo-drive

- planetary gearbox with minimum clearance (WHN9A/B/C, WH10NC)

- clearance-free gearing by timing belt (WH10CNC)

- gear set + gear ring

Group Guidance

- X, Y, Z axes – guideways reinforced with hardened steel plates, counterways with plastic casts, TURCITE-coated jibs

- W axis – sliding guideway, cast-iron / steel

- B axis – guideways of the rotary table are scrapped

Lubrication

- central, axial lubrication

- frequency of lubrication cycles correlates with travelled track of the particular group

Clamping

- B axis – hydraulically

- X, Y, Z,W axes – not clamped – positional feedback

Headstock

- sliding workspindle

- spindle cavity blown with air during tool-changing cycle

- spindle driven by four mechanical range – gears

- hydraulic shifting of each range

- headstock balancing – ropes and counterweight led in column

- setup of tool cooling by jets on headstock front side

Hydraulic Power Pack

- HYTOS hydraulic and lubrication set

- lubrication of all axes

- clamping B

- unclamping of the tool

Position Measurement

- HEIDENHAIN digital optical measuring

- X, Y, Z axes – absolute linear encoders

- W axis – absolute rotary encoder in motor

- B axis – absolute angle encoder

- S axis – incremental rotary encoder

Energy Distribution

- chain energy carriers

Coverage of Machine

- complete coverage of guideways of X, Z axes

- partial coverage of Y axis

Optionally

CE – compulsory in EU

- comprehensive safety elements according to the applicable legislation and technical standards

- operator housing

- working area of the machine is fenced off

Control System

- SIEMENS SIN 840D + handwheel

- SIEMENS drives and motors

ATC R03-30/40 – Automatic Tool Changer

- ATC facility as a separate unit

- magazine with servodrive for tool pocket positioning

- changer driven electrically / pneumatically

| ATC Parameters | R03-30 | R03-40 | |

| Tool changing time | 15 | 15 | s |

| Number of tools | 30 | 40 | pcs |

| Tool pocket pitch | 130 | 130 | mm |

| Maximum tool diameter – unrestricted | 125 | 125 | mm |

| Maximum tool diameter – with free pockets | 200 | 200 | mm |

| Maximum tool length | 500 | 480 | mm |

| Maximum tool weight | 15 | 15 | kg |

| Maximum weight of tools in magazine – total | 250 | 300 | kg |

| Maximum tool unbalance in magazine wheel | 50 | 70 | kg |

| Maximum wheel speed | 8 | 5 | rpm |

| Operating air pressure | 5 | 5 | bar |

| Required air purity | 40 | 40 | microns |

| Weight without tools | 1240 | 1380 | kg |

CHZ – Tool Cooling Kit – Emulsion

- tool cooling set with jets on headstock front side

- separate cooling unit – tank with pump and level gauge

- tank volume 105 l (usable)

- maximal pressure 4 bar / 32 l/min

- setup for tool cooling always included – distribution pipes, jets

CHZ-V – Tool Cooling – Air

- cold air gun

- cooling without a thermal shock

- positive impact on the accuracy and the surface quality

- high reliability

- environmentally friendly and low-noise operation

- almost zero operating costs

CHOV-K – Cooling Through Spindle Axis – Fluid

- not possible to add into configuration, once the production has started

- separate cooling unit with filter and magnetic swarf separator

- tank volume 1000 l

- maximal pressure 40 bar / 30 l/min

- other alterations to machine and CE features

- for pressure higher than 10 bar a workpiece or machine cover is necessary

CHOV-V – Cooling Through Spindle Axis – Air

- not possible to add into configuration, once the production has started

- maximum pressure 5 bar

CHOV-M – Cooling Through Spindle Axis – Oil-Mist

- not possible to add into configuration, once the production has started

- separate programmable cooling unit

- maximum pressure 5 bar

CHM – Oil-Mist Cooling

- can be added to machine at any time

- easy to assemble

- easy to use

Accessories

Standardly Delivered Accessories

- VP10–170 spindle guiding support

- VK-ISO50 cleaning brush

- clamping adapters – 15 pieces

- KM anchoring kit

- basic tool kit for operation and maintenance of the machine (only in case of selling a machine)

- basic spares kit

- accompanying technical documentation

Optional Accessories

- VP10–320 spindle guiding support

- VP10–470 spindle guiding support

- HPR50, FP40 vertical manual milling head

- UFP40 universal manual milling head

- LD650 facing head

- LN100X steady rest (tailstock) + technological accessories

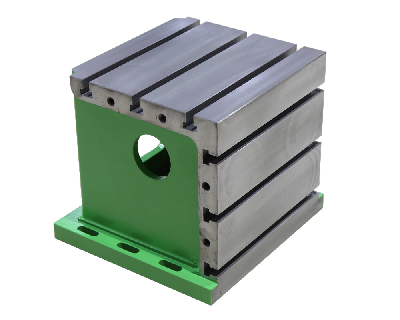

- UK500, UK1000, UK1500, UK2000 clamping cube

- UU800, UU950, UU1120, UU1450, UU1620 clamping angle plates

- spares kit for 3-year operation

- HEIDENHAIN DA 400 compressed-air filter system

- 3D touch probes with radio/infrared signal transmission (Heidenhain/Renishaw/Hexagon)

- HEIDENHAIN HR550 FS wireless handwheel

- CE security mode 3 (for the German market only)