(technical specification v08.03)

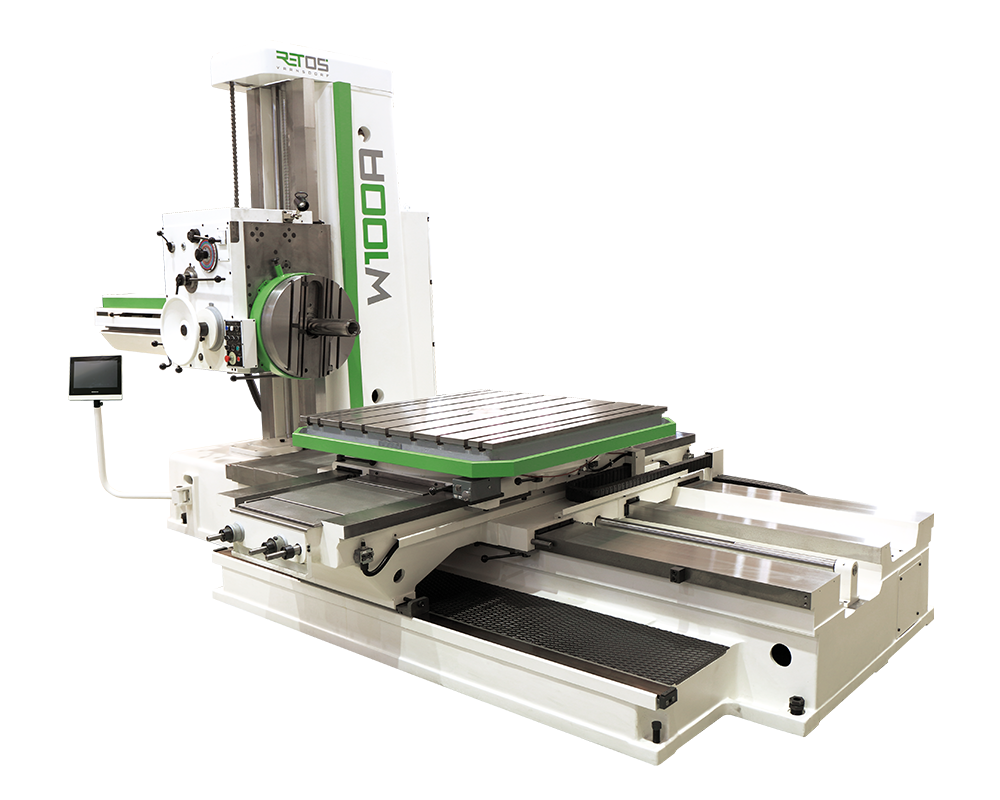

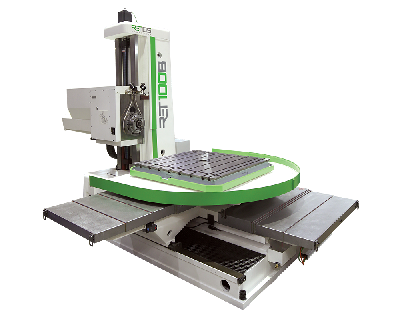

The W100A is the last design of the successful H100, H100A, W100, W100A machine series. It was the last conventional machine delivered by the parent company TOS Varnsdorf a.s. The company RETOS VARNSDORF s.r.o. took over the W100A production in 2005 and on the 1st of January 2009, it has become the sole distributor.

Features

- manually controlled horizontal boring machine

- fixed column, crosswise travelling table

- 4 linear axes, rotary table

- sliding workspindle

- facing head with tool slide

- machine designed for piece and low-volume engineering production

- suitable for roughing as well as for finishing

- option of fitting with digital optical measuring with DROs, tool cooling kit, steady rest, spindle clamping / guiding support, milling head etc.

Machine design can be customized.

Standard Version

Travelling Groups

- X – travel of rotary table slide on saddle

- Z – travel of saddle on bed

- Y – vertical headstock travel on column

- W – spindle stroke

- U – travel of tool slide of facing head

- B – table rotation

- S – rotation of workspindle and facing head

Group Guidance

- guideways on all linear axes are ground, counterways with plastic casts

- guideways on bed and saddle reinforced with hardened steel plates

- guideways of rotary table and facing head are scrapped

Lubrication

- HYTOS lubrication set

- central, time powered

- lubricates X, Y, Z, W, B axes – all at once

- U axis lubricated by grease nipples

Clamping

- X, Y, Z, W, B axes – manually by levers

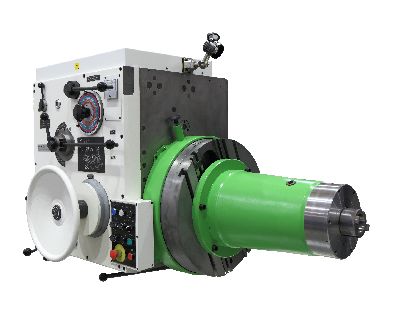

Headstock

- sliding workspindle + facing head

- hydraulic tool unclamping ISO50 (HUN) – lever clamp

- HYTOS hydraulic set

- asynchronous motor for driving the spindle speed and the feeds of all axes

- spindle speed and feeds driven in speed ranges – gears

- mechanical shifting of spindle speed and feeds

- most control elements are on the headstock

- headstock balancing – chain and counterweight led in column

Position Measurement

- PZI design – set up for additional mounting of rulers and DROs

- 4 x 90° optical table readout

Energy Distribution

- X, Z, W axes – chain energy carriers

- Y axis – protective tube

Coverage of Machine

- bed guideways between column and saddle partly protected by telescopic way covering

Voltage Options

- 50Hz – 3 x 400V, 3 x 415V, 3 x 500V

- 60Hz – 3 x 220V, 3 x 440V, 3 x 460V, 3 x 480V, 3 x 575V

- parameters of electric parts given in the tables are valid for option 3 x 400V / 50Hz

Optionally

HEIDENHAIN Position Measurement

- digital optical measuring with DRO

- DRO PT8016 for measuring of X, Y, Z, W, B axes

- DRO ND7013 for measuring of X, Y, Z axes

- X, Y, Z, W axes – incremental linear encoders

- B axis – incremental rotary encoder

CE – compulsory in EU

- comprehensive safety elements according to the applicable legislation and technical standards

- adjustable operator cover on headstock

- original spoke handwheel replaced by new filled one

- stairs to headstock

- working area of the machine is fenced off

Tool clamping options

- clamping Morse MK6 tool

- motorical tool clamping ISO50 (MUN) – ball clamp

| List of Supported Standards of Tool Shanks / Clamping Adapters (MUN) |

| Tool shank |

Standard |

Adapter |

| Long shank – metric |

ČSN 220432 |

4100597 |

| Long shank – metric |

DIN 2080 |

4100597 |

| Long shank – inch |

NMTB 50 |

4100892 |

| Short shank – metric |

ČSN 220434 |

4100809 |

| Short shank – metric |

DIN 69871 |

4100809 |

| Short shank – metric |

MAS BT 403-1982 |

4100809 |

| Short shank – inch |

CAT ANSI / ASME B5.50-1985 |

4100913 |

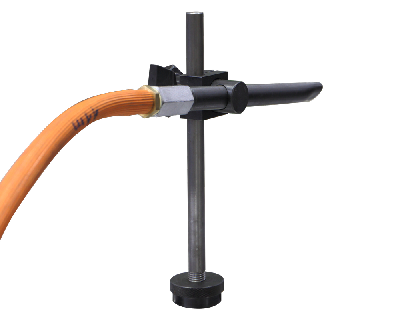

CHZ – Tool Cooling Kit – Emulsion

- tool cooling kit with portable jet on magnetic stand

- separate cooling unit – tank with pump

- tank volume 50 l (usable)

- maximum pressure 0,4 bar / 25 l/min

Telescopic X axis cover

- full coverage of X axis guideways

- replaces partial sliding cover of saddle

- enlarges machine layout

Accessories

Standardly Delivered Accessories

- SP100-100 spindle clamping support

- small DN100 tool holder

- VK-ISO50 cleaning brush

- clamping adapters – 15 pieces

- KM anchoring kit

- basic tool kit for operation and maintenance of the machine

- basic spares kit

- accompanying technical documentation

Optional Accessories

- PP100 portable control panel

- CHZ100 tool cooling kit by emulsion

- CHZ-V tool cooling by air

- spindle cavity blown with air

- PVD100-550 spindle guiding support

- SP100-500 spindle clamping support

- SP100-200/800 spindle clamping support up to 800 rpm

- FP40-100 vertical milling head

- UFP40-100 universal milling head

- RZ100 change gear kit for thread cutting

- TD50 telescopic tool holder

- VHU-ISO50 boring heads

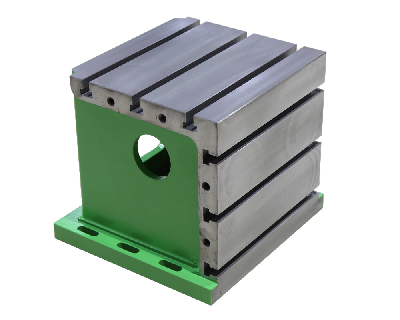

- UK500, UK1000, UK1500, UK2000 clamping cube

- UU800, UU950, UU1120, UU1450, UU1620 clamping angle plates

- spares kit for 3-year operation

- KT130 HEIDENHAIN touch probe

- transport bars (necessary in the container)

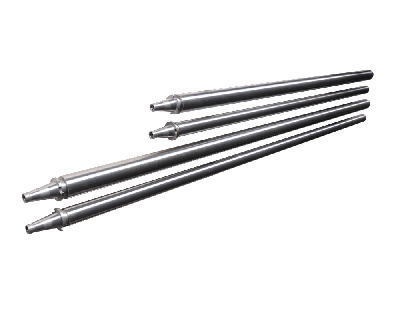

Optional Accessories – Machine with Steady Rest

- steady rest (tailstock) LN100

- VT80-2500-ISO50 smooth boring bar

- VT80-3150-ISO50 smooth boring bar

- VT100-2500-ISO50 smooth boring bar

- VT100-3150-ISO50 smooth boring bar

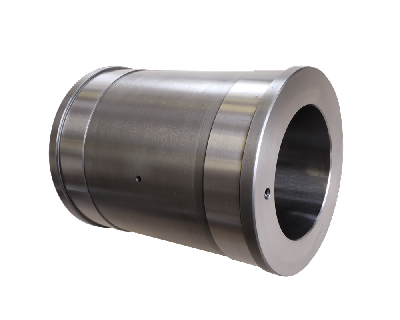

- LLK-150/80 sliding bush of the steady rest

- LLK-150/100 sliding bush of the steady rest

- VH80, VH100 three-tool boring heads

| Steady Rest Parameters |

| Distance between hollow spindle face and steady rest bearing |

2800 |

mm |

| Bearing axis height above table |

0 - 1120 |

mm |

| Rapid traverse of bearing |

696 |

mm / min |

| Bearing bore |

150 H7 |

mm |

| Motor power of steady rest |

0,55 |

kW |

| Motor speed of steady rest |

2780 |

rpm

|