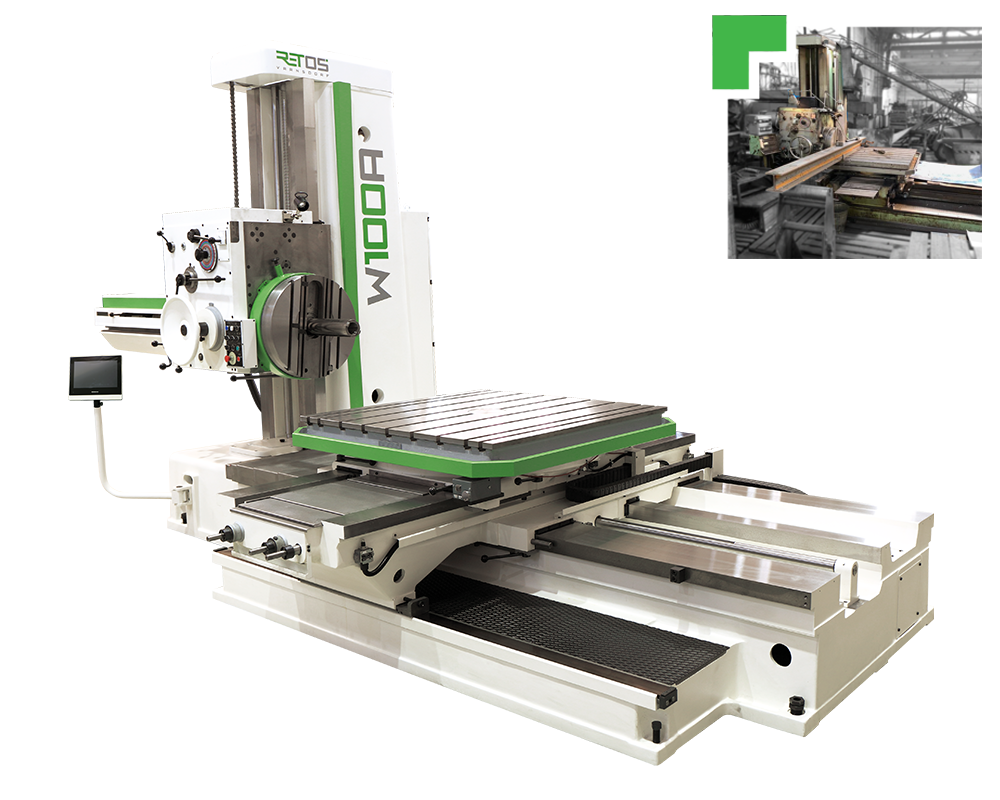

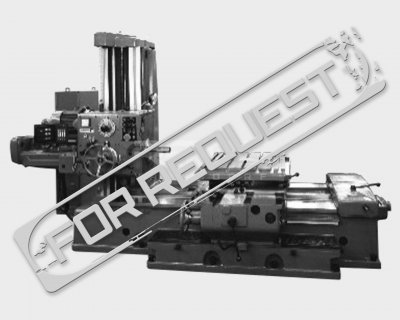

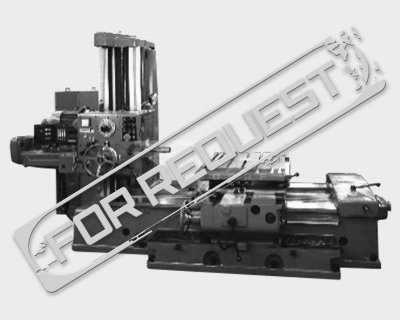

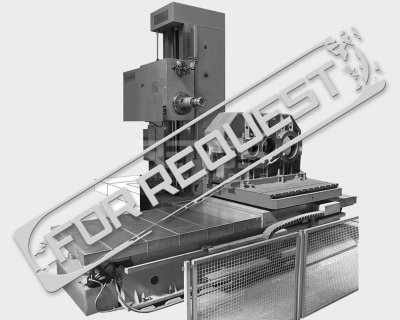

W100A-R

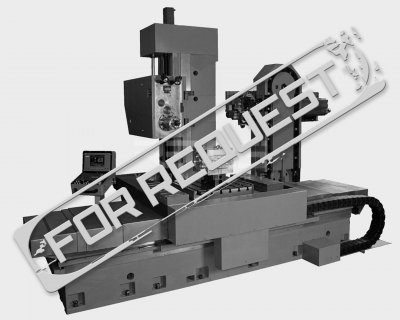

Conventional horizontal boring mill – table type

- solid design

- travel in the X axis – 1600 mm

- almost indistinguishable from a new machine

- same parameters as a new machine

- the same range of accessories as a new machine

- this presentation covers the machine types of the series W100 and W100A

Main Parameters

| Workspindle diameter | 100 | mm |

| Clamping taper | 50 | ISO |

| Spindle speed range | 1120 | rpm |

| Table transversal travel (X) | 1600 | mm |

| Headstock travel (Y) | 1120 | mm |

| Table longitudinal travel (Z) | 1250 / 1750 | mm |

| Spindle stroke (W) | 900 | mm |

| Table clamping surface | max. 1500 x 1500 | mm x mm |

| Table loading capacity | max. 5000 | kg |

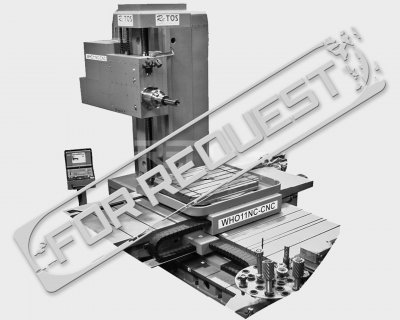

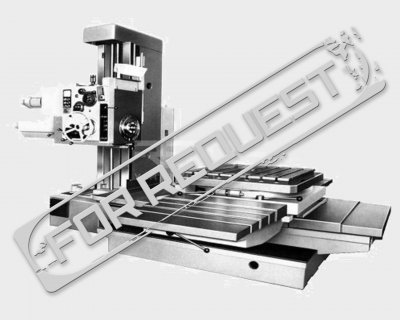

Gallery

Complete Parameters

| Machine Parameters | ||

| Workspindle diameter | 100 | mm |

| Clamping taper | 50 | ISO |

| Spindle speed range – 23 gears | 7,1 - 1120 | rpm |

| Main motor power | 11 | kW |

| Main motor speed | 1460 | rpm |

| Maximum torque of the spindle – Nmin | 3350 | Nm |

| Maximum torque of the spindle – Nmax | 78,5 | Nm |

| X…transversal travel of table | 1600 (1800 **) | mm |

| Z…longitudinal travel of table – short bed (without steady rest) | 810 | mm |

| Z…longitudinal travel of table – long bed (with / without steady rest) | 1250 | mm |

| Z…longitudinal travel of table – long bed (with / without steady rest) | 1750 | mm |

| Y...vertical travel of headstock – table 1250 x 1250 | 1120 | mm |

| Y...vertical travel of headstock – table 1500 x 1500 | 1100 | mm |

| W…spindle stroke | 900 | mm |

| Table clamping surface | 1250 x 1250 | mm x mm |

| 1500 x 1500 | mm x mm | |

| Width of T-slots | 22 H8 * | mm |

| Table loading capacity – 1250 x 1250 | 3000 (5000 ***) | kg |

| Table loading capacity – 1500 x 1500 | 2500 (5000 ***) | kg |

| Feeds...X, Y, Z, W, U – 18 gears | 18 - 900 | mm / min |

| Feeds...X, Y, Z, W, U – 32 gears | 0,02 - 12 | mm / rev |

| Thread feeds...X, Y, Z, W, U – metric – 18 gears | 0,25 - 12 | mm / rev |

| Thread feeds...X, Y, Z, W, U – inch – 18 gears | 120 - 2,5 | "threads / 1""" |

| Rapid traverse...X, Y, Z, W, U | 2800 | mm / min |

| Rapid traverse of table rotation...B | 1 | rpm |

| Total power consumption | 15 | kVA |

| Machine and accessories standard colour | white 9010 / green 6018 | RAL |

| Fence standard colour | black 9011 / yellow 1018 | RAL |

| Machine weight | 14000 | kg |

| Total area including CE – approximate | 5000 x 7500 | mm x mm |

| * the T-slot width of overhauled machines is usually 23/24 mm | ||

| ** option, reduction of accuracy / loading capacity in end travel positions of X axis | ||

| *** option, limited X = 1200 mm, centered workpiece | ||

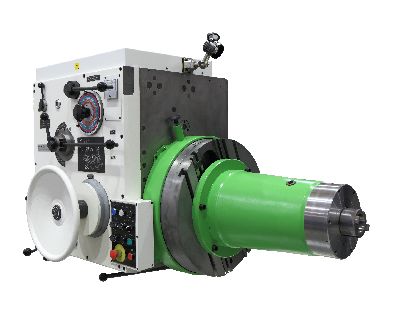

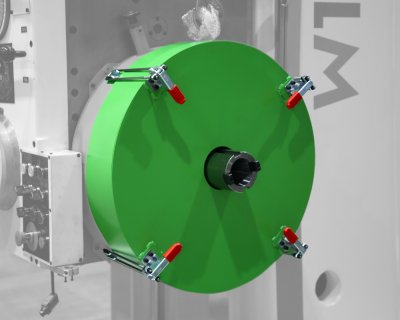

| Facing Head Parameters | ||

| Facing head diameter | 600 | mm |

| Centering hole diameter / depth | 280H6 / 8 | mm |

| U...tool slide travel | 210 | mm |

| Maximal facing diameter | 900 | mm |

| Facing head speed range – 16 gears | 7,1 - 224 | rpm |

| List of Supported Standards of Tool Shanks / Clamping Adapters (HUN) | ||

| Tool shank | Standard | Adapter |

| Long shank – metric | ČSN 220432 | 4100744 |

| Long shank – metric | DIN 2080 | 4100744 |

| Long shank – inch | NMTB 50 | 4100988 |

| Short shank – metric | ČSN 220434 | 4100793 |

| Short shank – metric | DIN 69871 | 4100793 |

| Short shank – metric | MAS BT 403-1982 | 4100793 |

| Short shank – inch | CAT ANSI / ASME B5.50-1985 | 4100917 |

| List of Supported Standards of Tool Shanks / Clamping Adapters (MUN) | ||

| Tool shank | Standard | Adapter |

| Long shank – metric | ČSN 220432 | 4100597 |

| Long shank – metric | DIN 2080 | 4100597 |

| Long shank – inch | NMTB 50 | 4100892 |

| Short shank – metric | ČSN 220434 | 4100809 |

| Short shank – metric | DIN 69871 | 4100809 |

| Short shank – metric | MAS BT 403-1982 | 4100809 |

| Short shank – inch | CAT ANSI / ASME B5.50-1985 | 4100913 |

| Steady Rest Parameters | ||

| Distance between hollow spindle face and steady rest bearing | 2800 | mm |

| Bearing axis height above table | 0 - 1120 | mm |

| Rapid traverse of bearing | 696 | mm / min |

| Bearing bore | 150 H7 | mm |

| Motor power of steady rest | 0,55 | kW |

| Motor speed of steady rest | 2780 | rpm |

Technical specification

(technical specification v08.00)

Features

- manually controlled horizontal boring machine

- fixed column, crosswise travelling table

- 4 linear axes, rotary table

- sliding workspindle

- facing head with tool slide

- machine designed for piece and low-volume engineering production

- suitable for roughing as well as for finishing

- option of fitting with digital optical measuring with DROs, tool cooling kit, steady rest, spindle clamping / guiding support, milling head etc.

Machine design can be customized.

Standard Version

Travelling Groups

- X – travel of rotary table slide on saddle

- Z – travel of saddle on bed

- Y – vertical headstock travel on column

- W – spindle stroke

- U – travel of tool slide of facing head

- B – table rotation

- S – rotation of workspindle and facing head

Group Guidance

- guideways on all linear axes are ground, counterways with plastic casts

- guideways on bed and saddle reinforced with hardened steel plates

- guideways of rotary table and facing head are scrapped

Lubrication

- HYTOS lubrication set

- central, time powered

- lubricates X, Y, Z, W, B axes – all at once

- U axis lubricated by grease nipples

Clamping

- X, Y, Z, W, B axes – manually by levers

Headstock

- sliding workspindle + facing head

- hydraulic tool unclamping ISO50 (HUN) – lever clamp

- HYTOS hydraulic set

- asynchronous motor for driving the spindle speed and the feeds of all axes

- spindle speed and feeds driven in speed ranges – gears

- mechanical shifting of spindle speed and feeds

- most control elements are on the headstock

- headstock balancing – chain and counterweight led in column

Position Measurement

-

PZI design – set up for additional mounting of rulers and DROs

Energy Distribution

- X, Z, W axes – chain energy carriers

- Y axis – protective tube

Coverage of Machine

- bed guideways between column and saddle partly protected by telescopic way covering

Voltage Options

- 50Hz – 3 x 400V, 3 x 415V, 3 x 500V

- 60Hz – 3 x 220V, 3 x 440V, 3 x 460V, 3 x 480V, 3 x 575V

- parameters of electric parts given in the tables are valid for option 3 x 400V / 50Hz

Optionally

HEIDENHAIN Position Measurement

- digital optical measuring with DRO

- DRO PT8016 for measuring of X, Y, Z, W, B axes

- DRO ND7013 for measuring of X, Y, Z axes

- X, Y, Z, W axes – incremental linear encoders

- B axis – incremental rotary encoder

- 4 x 90° optical table readout

CE – compulsory in EU

- comprehensive safety elements according to the applicable legislation and technical standards

- adjustable operator cover on headstock

- original spoke handwheel replaced by new filled one

- stairs to headstock

- working area of the machine is fenced off

Tool clamping options

- clamping Morse MK6 tool

- motorical tool clamping ISO50 (MUN) – ball clamp

| List of Supported Standards of Tool Shanks / Clamping Adapters (MUN) | ||

| Tool shank | Standard | Adapter |

| Long shank – metric | ČSN 220432 | 4100597 |

| Long shank – metric | DIN 2080 | 4100597 |

| Long shank – inch | NMTB 50 | 4100892 |

| Short shank – metric | ČSN 220434 | 4100809 |

| Short shank – metric | DIN 69871 | 4100809 |

| Short shank – metric | MAS BT 403-1982 | 4100809 |

| Short shank – inch | CAT ANSI / ASME B5.50-1985 | 4100913 |

Telescopic X axis cover

- full coverage of X axis guideways

- replaces partial sliding cover of saddle

- enlarges machine layout

Accessories

Standardly Delivered Accessories

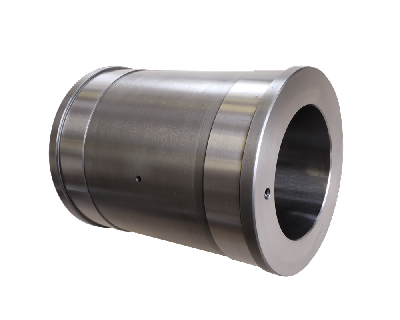

- SP100-100 spindle clamping support

- small DN100 tool holder

- VK-ISO50 cleaning brush

- clamping adapters – 15 pieces

- KM anchoring kit

- basic tool kit for operation and maintenance of the machine

- basic spares kit

- accompanying technical documentation

Optional Accessories

- PP100 portable control panel

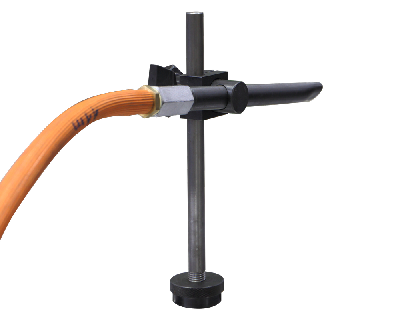

- CHZ100 tool cooling kit by emulsion

- CHZ-V tool cooling by air

- spindle cavity blown with air

- PVD100-550 spindle guiding support

- SP100-500 spindle clamping support

- SP100-200/800 spindle clamping support up to 800 rpm

- FP40-100 vertical milling head

- UFP40-100 universal milling head

- RZ100 change gear kit for thread cutting

- TD50 telescopic tool holder

- VHU-ISO50 boring heads

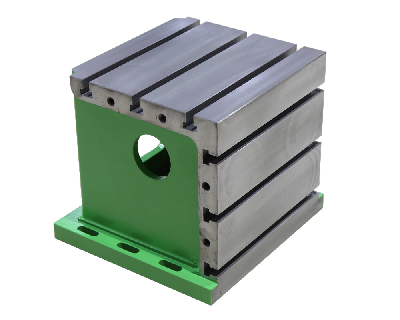

- UK500, UK1000, UK1500, UK2000 clamping cube

- UU800, UU950, UU1120, UU1450, UU1620 clamping angle plates

- spares kit for 3-year operation

- KT130 HEIDENHAIN touch probe

- transport bars (necessary in the container)

Optional Accessories –Machine with Steady Rest

- steady rest (tailstock) LN100

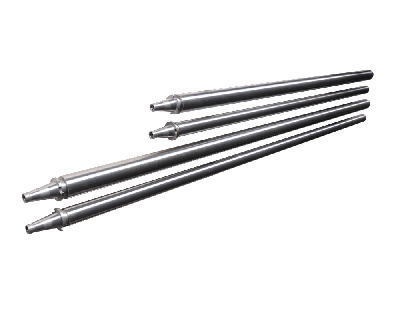

- VT80-2500-ISO50 smooth boring bar

- VT80-3150-ISO50 smooth boring bar

- VT100-2500-ISO50 smooth boring bar

- VT100-3150-ISO50 smooth boring bar

- LLK-150/80 sliding bush of the steady rest

- LLK-150/100 sliding bush of the steady rest

- VH80, VH100 three-tool boring heads

| Steady Rest Parameters | ||

| Distance between hollow spindle face and steady rest bearing | 2800 | mm |

| Bearing axis height above table | 0 - 1120 | mm |

| Rapid traverse of bearing | 696 | mm / min |

| Bearing bore | 150 H7 | mm |

| Motor power of steady rest | 0,55 | kW |

| Motor speed of steady rest | 2780 | rpm |